Breakthroughs in Logistics Pallet Injection Molding: Bole EPL Machines’ Technological Solutions

Industrial Transformation Stable Efficient Energy saving Leading comprehensive pallet solutions!

In modern logistics and warehousing systems, plastic pallets serve as fundamental and critical load-bearing devices, whose quality directly impacts logistics efficiency and operational costs. However, due to their large size, complex structure, and harsh service environment, injection molding of pallets has long been plagued by multiple technical challenges. Ensuring dimensional stability, reliable strength, and cost control under high-load, long-flow production conditions has become a universal focus of the industry.

Seven Core Challenges in Pallet Injection Molding 01.Complex Raw Materials:Frequent incorporation of recycled materials leads to unstable compositions and a narrow processing window, demanding high equipment plasticizing and homogenizing capabilities. 02.Warpage & Deformation: Large dimensions and uneven wall thickness cause inconsistent cooling shrinkage, resulting in warpage, torsion, or surface sagging, which impairs flatness and stacking stability. 03.Difficult Dimensional Control:As standardized tools, pallets require strict dimensional tolerances. Materials such as PP and HDPE have high shrinkage rates, and even minor fluctuations in process parameters can lead to out-of-tolerance dimensions. 04.Mold Filling Difficulty: Long flow paths and large projected areas easily cause premature melt cooling, requiring high injection pressure. This results in obvious weld lines and structural weak points at the intersections of reinforcing ribs. 05.Concentrated Internal Stress: Rapid mold filling and cooling freeze molecular chains, generating internal stress that exacerbates deformation and may even cause low-temperature brittle cracking. 06.Uncontrollable Color & Appearance: :Recycled materials lead to dull colors and significant batch-to-batch color differences. Deep-color masterbatches are often added, which further affect heat dissipation and weather resistance. Surface defects such as flow marks and pitting are also common. 07.High Energy Consumption & Long Cycle Time:Extended cooling time leads to low production efficiency and high energy consumption per unit.

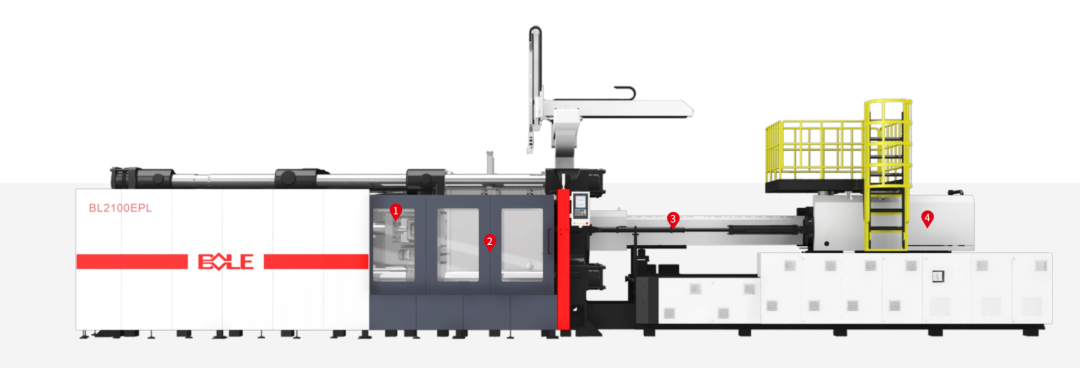

Bole's Solution: EPL Pallet-Specialized Injection Molding Machines – Technological Breakthroughs To address the above industry-wide challenges, Bole Machinery leveraged its years of technical expertise in large-scale injection molding equipment and launched the EPL series pallet-specialized injection molding machines. Through systematic improvements in structure, plasticization, and energy efficiency, it provides customers with a highly stable and efficient production solution. Central Clamping Toggle System: Root-Cause Suppression of Deformation Bole's patented central clamping toggle system offers:Large mold stroke and wide tie-bar spacing for strong mold compatibility, adapting to large-scale molds.Uniform clamping force distribution, reducing warpage and torsion caused by uneven stress.100% clamping force utilization, lowering internal stress of products and enhancing dimensional stability and durability. Specialized Plasticizing System: Mastering Complex Raw Materials Specialized Plasticizing System: Mastering Complex Raw Materials.A special screw color-mixing design ensures excellent color uniformity, a glossy surface, and reduced color differences and flow marks.A standard nozzle filter effectively traps impurities in recycled materials, protecting molds from damage. Wide Range of Large-Tonnage Clamping Force Options: Meeting High-Load Molding Requirements The Bole EPL series offers clamping force options from 2,000 to 4,000 tons, fully covering the production needs of:Lightweight standard pallets (e.g., 1200×1000mm block, stringer, and nine-leg pallets).Heavy-duty reinforced pallets (e.g., 1400×1200mm double-sided grid and insert-structured pallets)Large special-specification pallets.Precise tonnage matching ensures mold stability and dense product formation under high-pressure injection, meeting stringent requirements for dimensions and strength. Bole Energy-Saving System: Tangible Cost Reduction & Efficiency Improvement Integrating electric pre-plasticization, servo energy-saving oil temperature control units, and Bole's intelligent control system, the overall energy consumption is reduced by 20%-40% compared with traditional servo machines.Optimized cooling and cycle management shortens non-essential waiting time, boosting production efficiency. Significantly Shortened Cycle Time & Improved Efficiency Targeting the core bottleneck of slow cooling and long cycle times, the Bole EPL series integrates multiple key technologies for high-efficiency production:Optimized cooling and ejection systems reduce mold idle time.High-performance plasticizing capacity and high-speed, high-pressure injection units enable rapid melt preparation and mold filling, reducing cooling waiting time.An intelligent cycle management system automatically optimizes process parameters to balance product quality and production speed.The overall production cycle is shortened by 10%-25%, ensuring quality while increasing output and reducing unit cost. Market Recognition & Continuous Innovation The Bole EPL pallet-specialized injection molding machines have been successfully put into application in many large domestic logistics equipment manufacturers. They have won widespread customer recognition for their stable molding quality, outstanding energy-saving performance, and strong raw material adaptability. Bole EPL Palletizer Live Shot from the Production Site