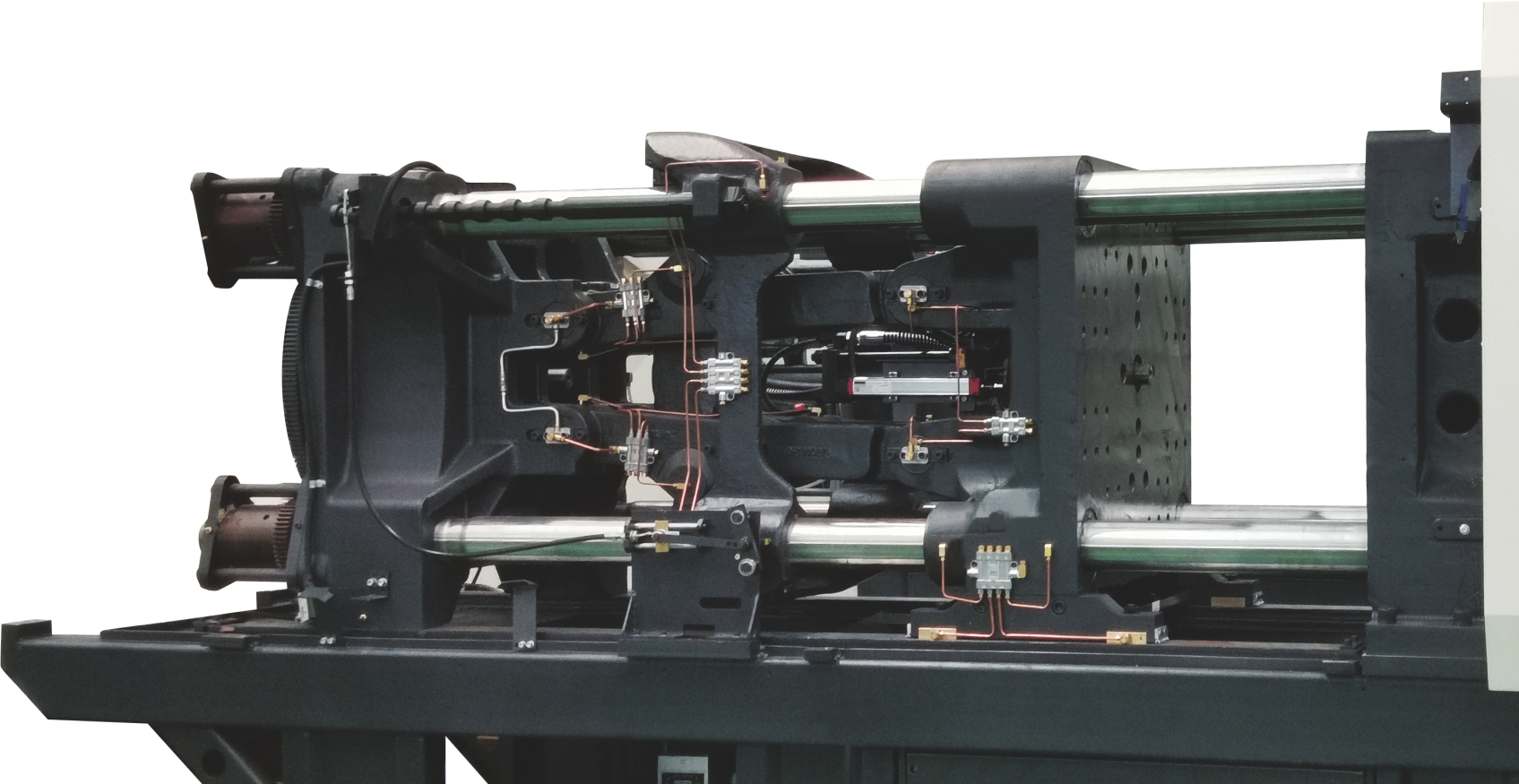

·Comprehensively optimized hydraulic system, the system pressure has been increased to 17.5MPA to increase the injection pressure

·Upgraded to the third generation high-performance servo system, the system response time is faster and more energy-saving. The entire series of models was tested in accordance with the GB/T30200-2013 standard, and the energy consumption ≤0.4kW.h/kg was rated as Level 1