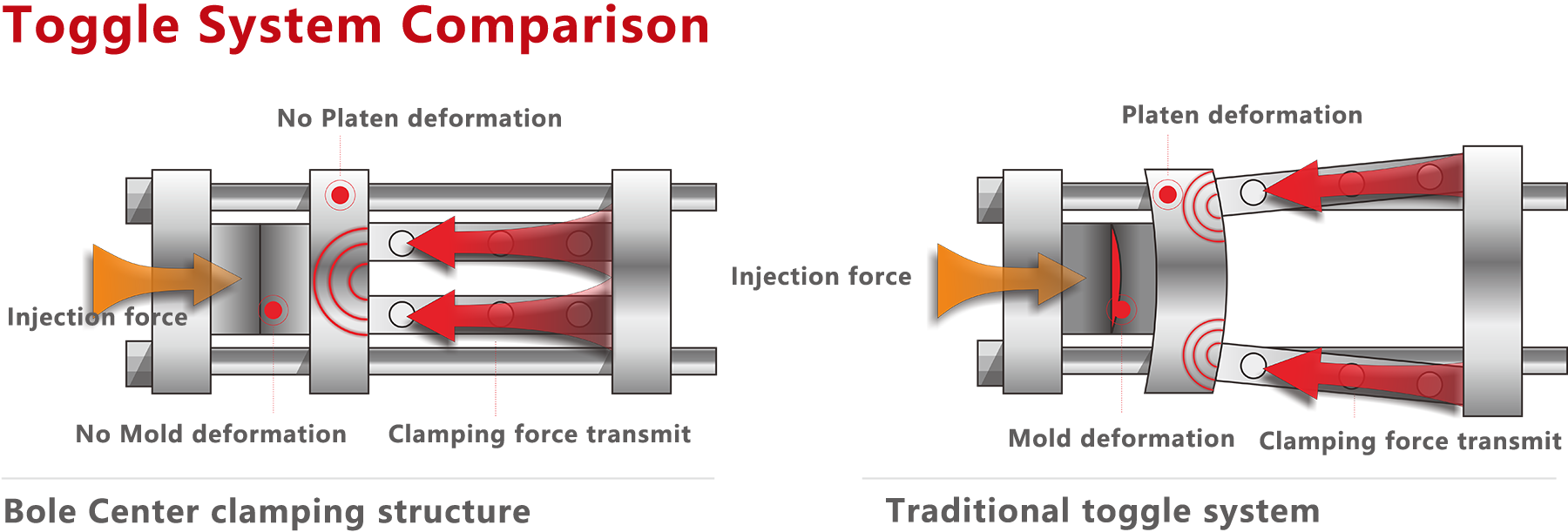

Traditional three-panel structure

It occupies a large area; changes in mold temperature will cause changes in clamping force; the connecting rod pin is easy to wear

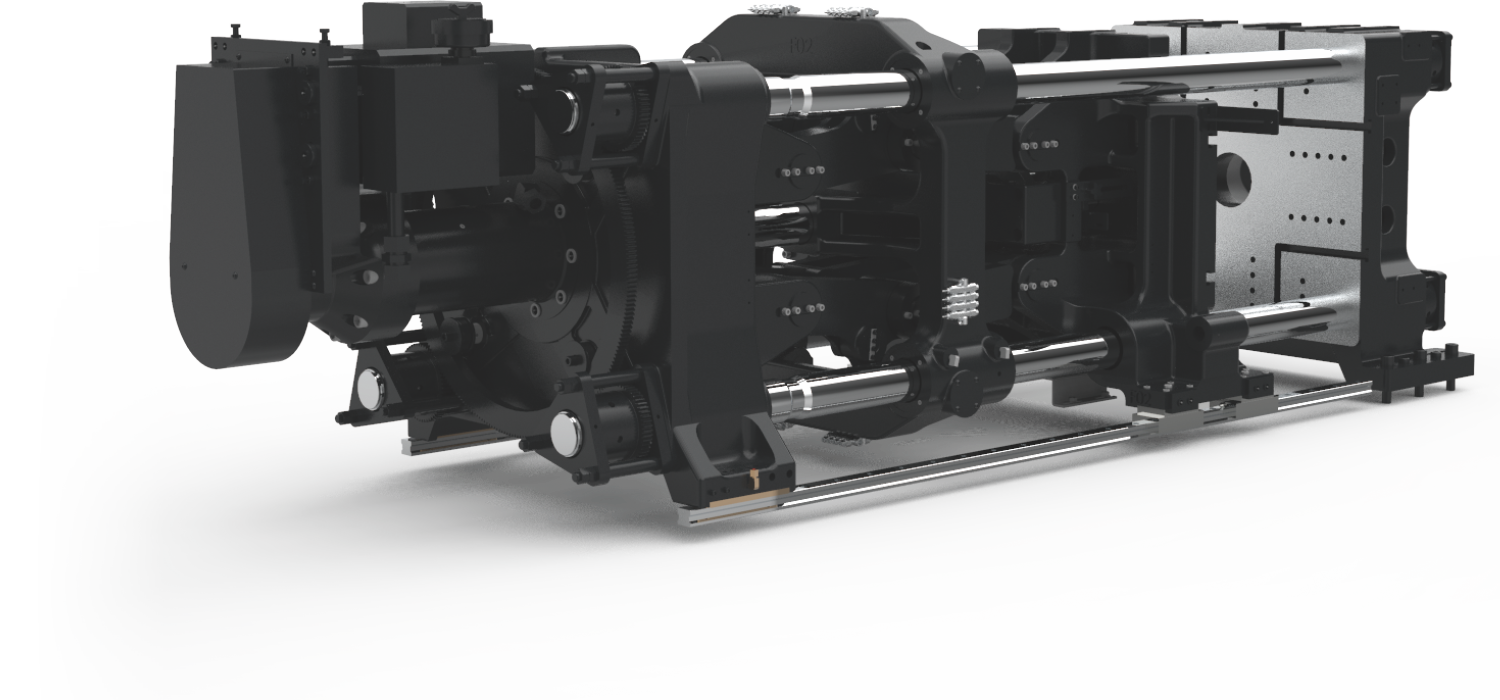

Two-plate clamping structure

It occupies a small area and is more suitable for super-large equipment! Two-plate clamping structure, four-cylinder flexible independent control, better mold adaptability, excellent performance, and covers an area of 20% less

Large injection volume

The screw diameter is 170mm and the length exceeds 4m, breaking through the material manufacturing bottleneck, with a maximum injection output of >17kg; the screw is made of super heat-resistant and high-strength material with a CO/MO content of over 14wt.%, which can cope with high-temperature environments above 650°C, ensuring that it remains strong for long-term use.

Independently developed key heating control algorithms to solve the problem of insufficient heat under large melting volumes

Innovative and efficient composite heating scheme, high heating power, combined with self-developed pre-response temperature compensation control system, ensure the continuous and stable transformation of magnesium alloy semi-solid melt under large pulping volumes.