EKW servo energy saving

Wide plate injection molding machine

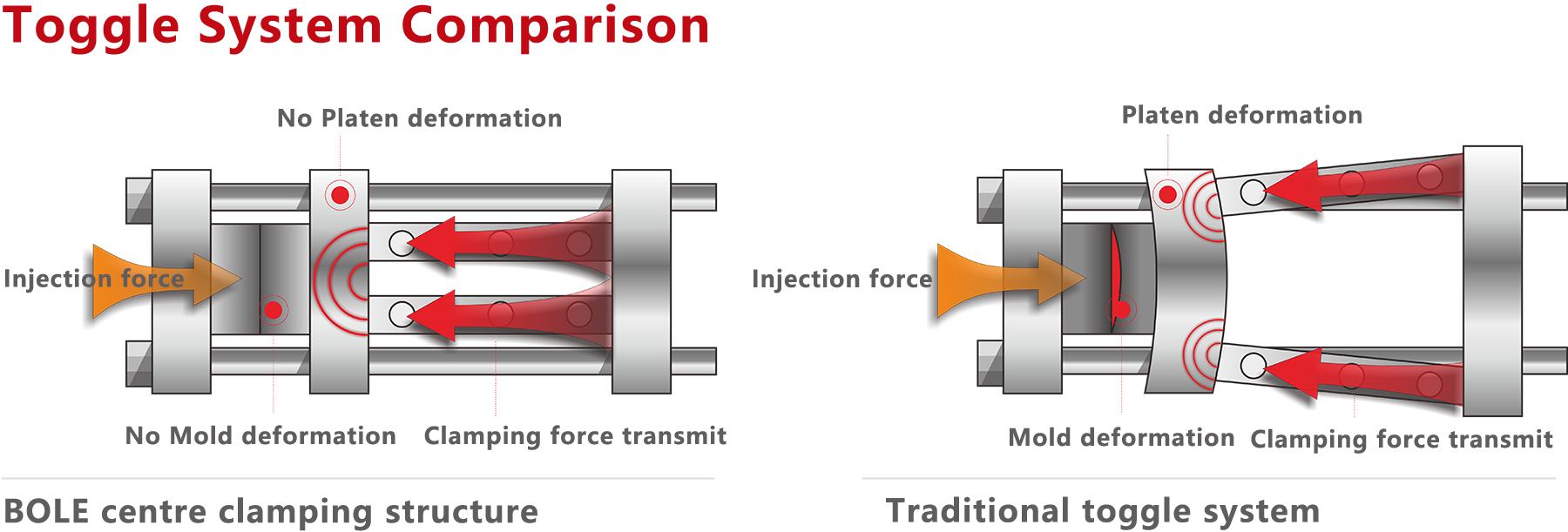

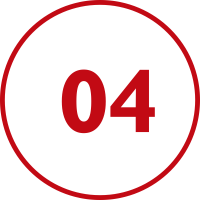

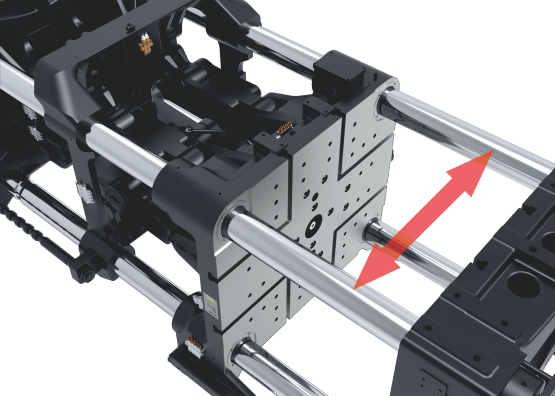

·Increased rigidity (the mold closing part is optimized to improve the rigidity of the mold closing part and further extend the service life of the machine)

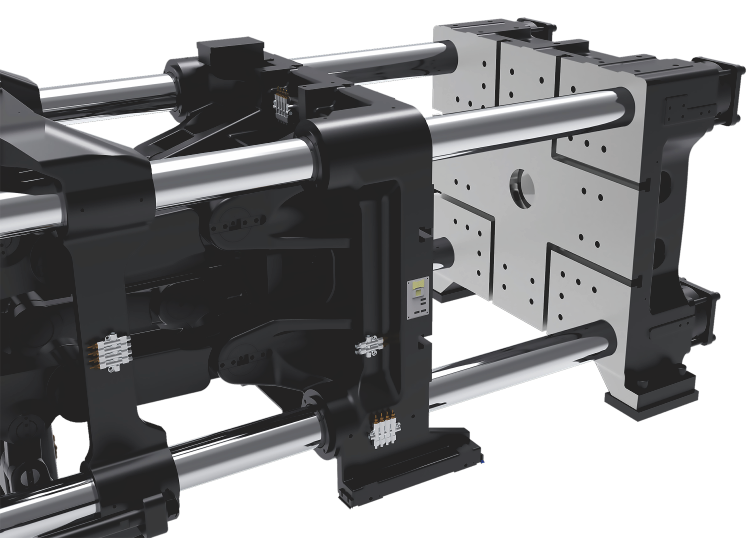

The center hole of the head plate is reduced accordingly according to China’s new national industry standards, increasing the rigidity of the middle part

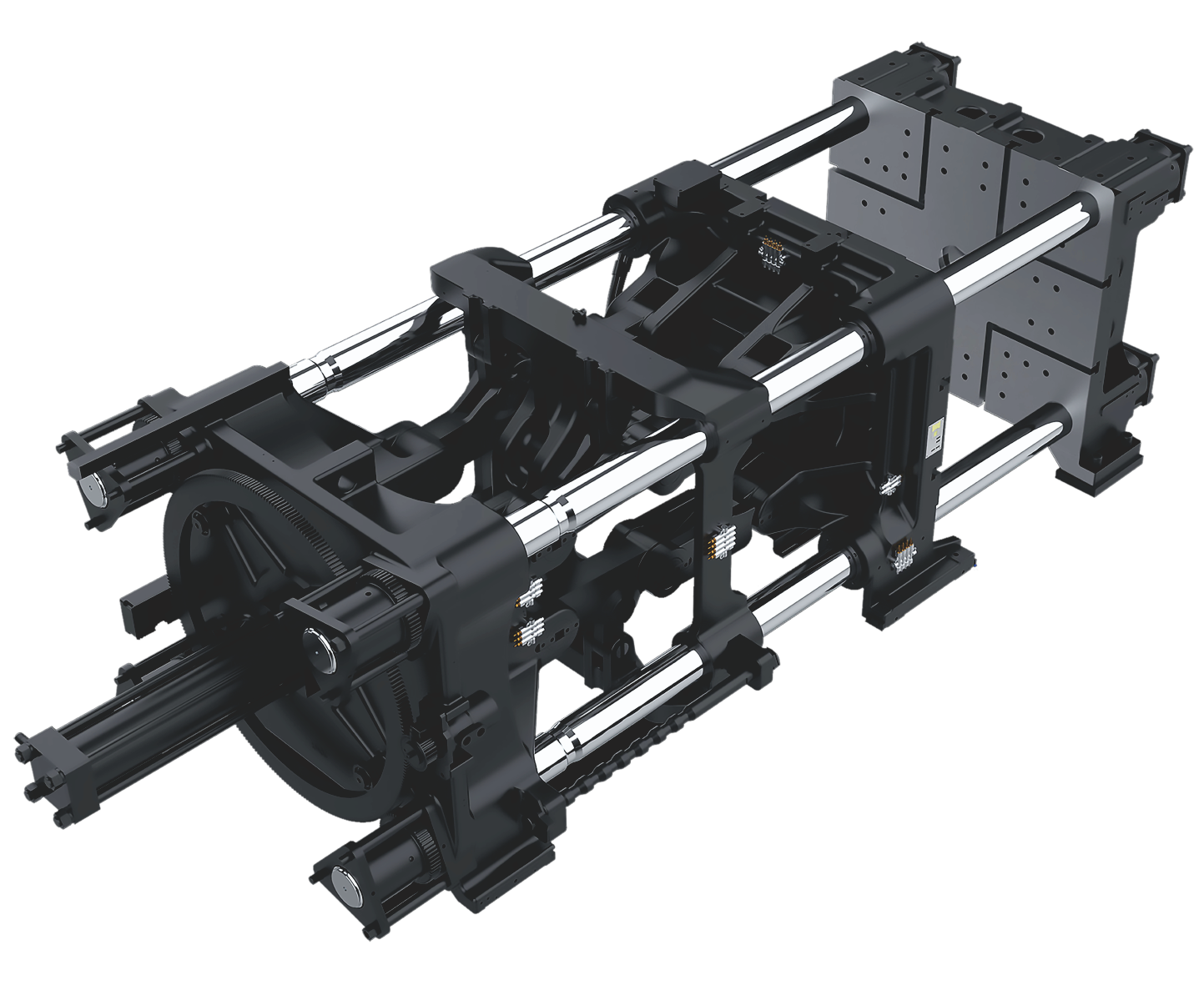

Save melting time, the plasticizing unit is designed in Germany, the plasticizing efficiency is fast, and the melting time is saved