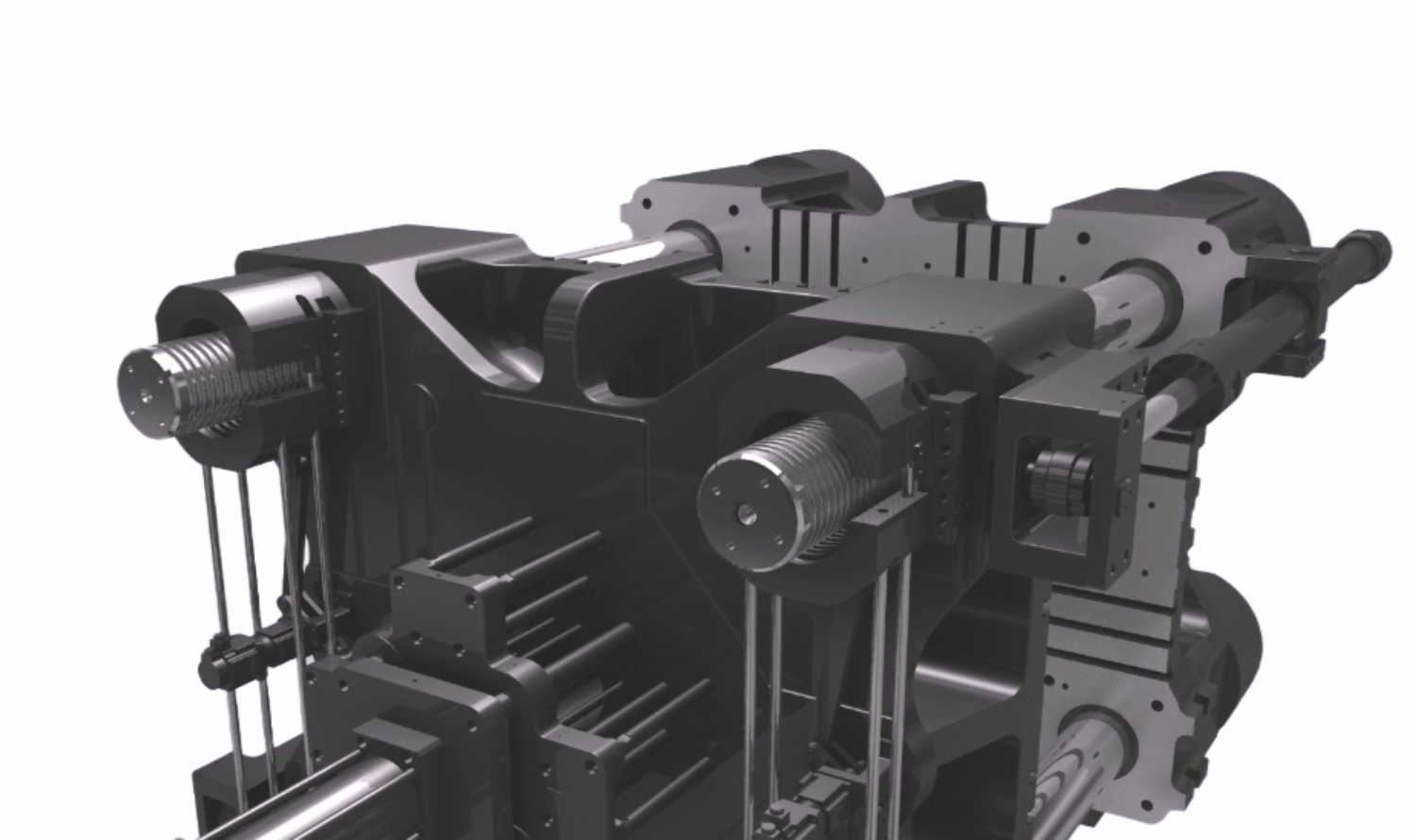

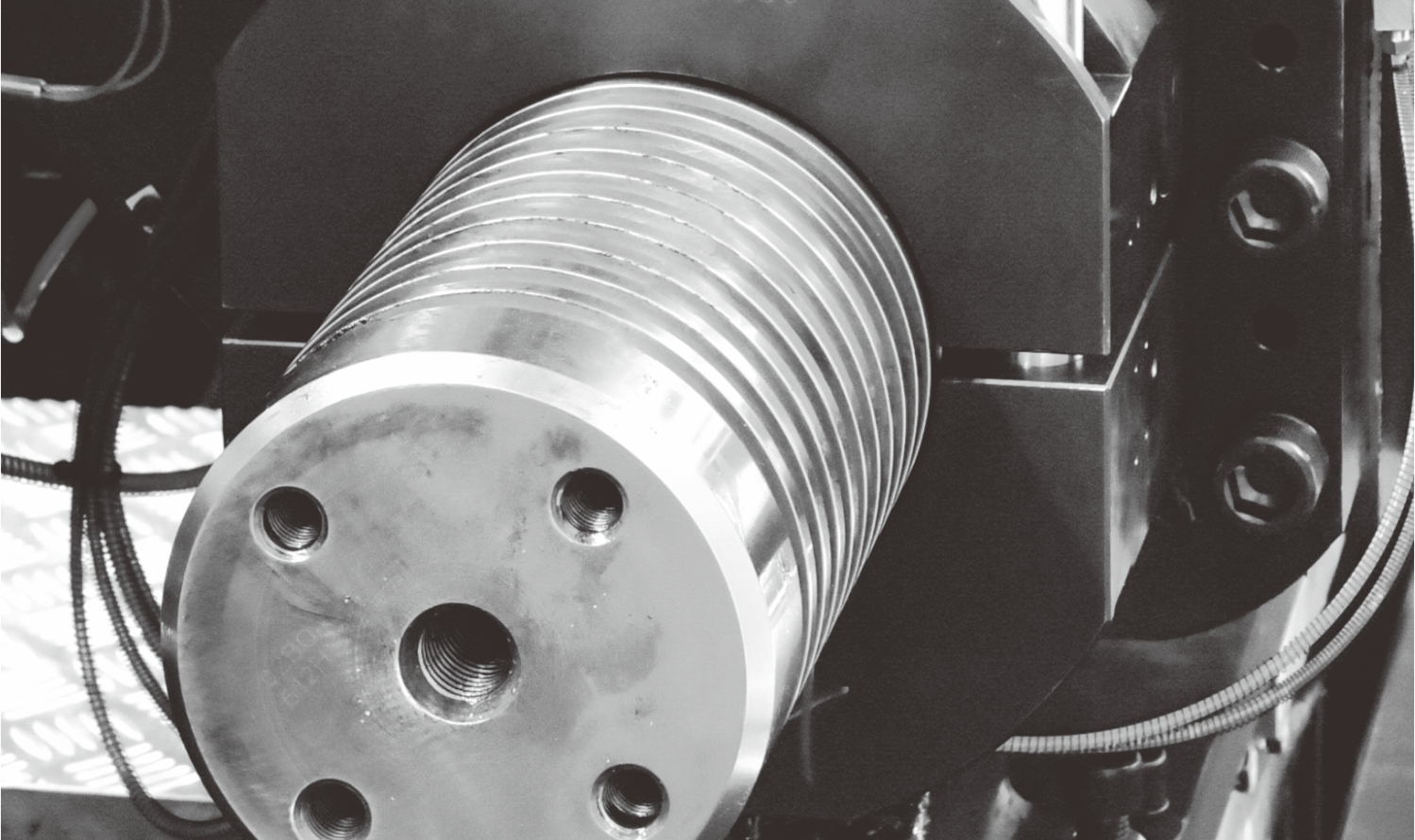

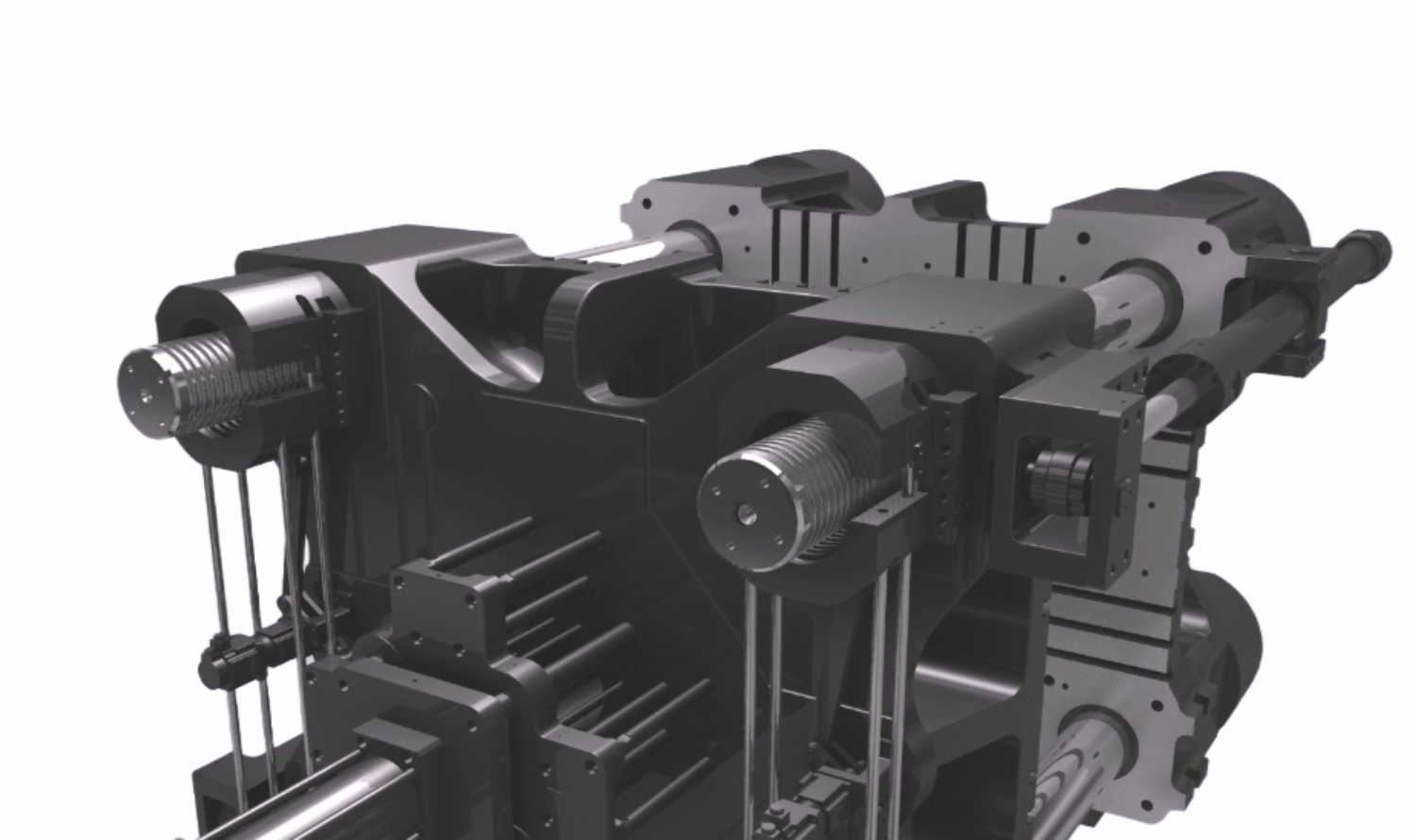

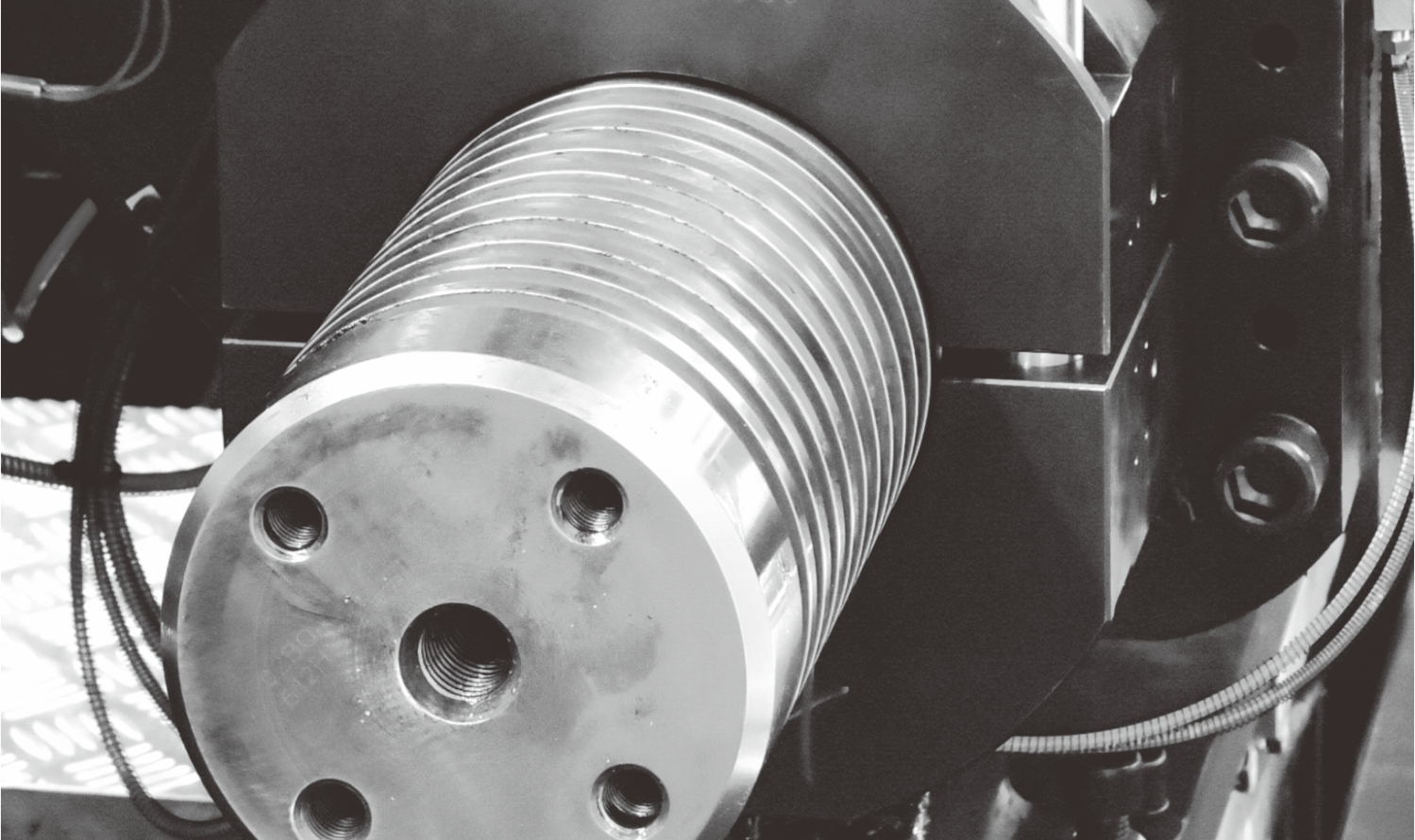

The patented anti-breakage tie rod design eliminates stress concentration points and reduces the risk of concentrated stress points on the tie rod, thereby effectively reducing the risk of breakage.

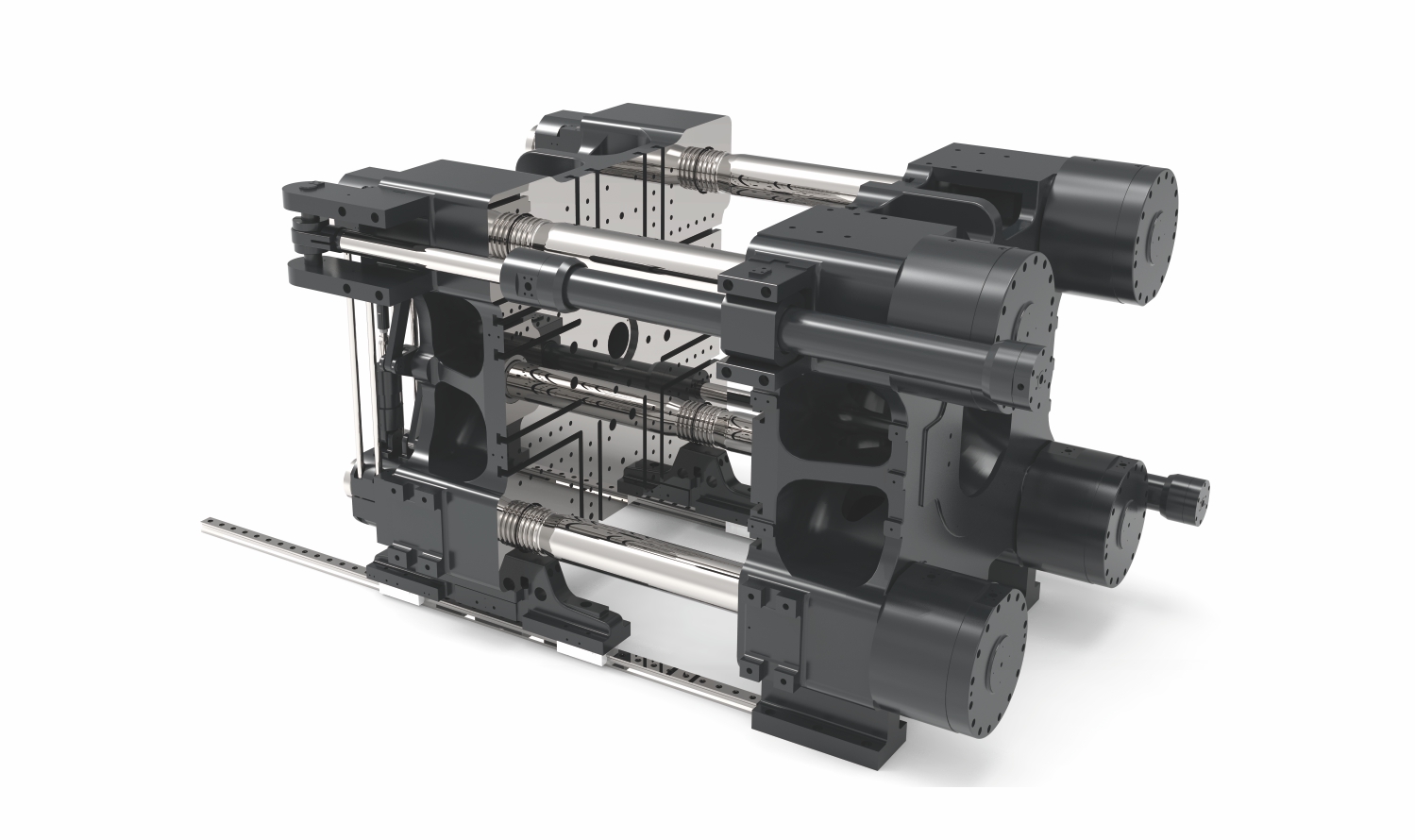

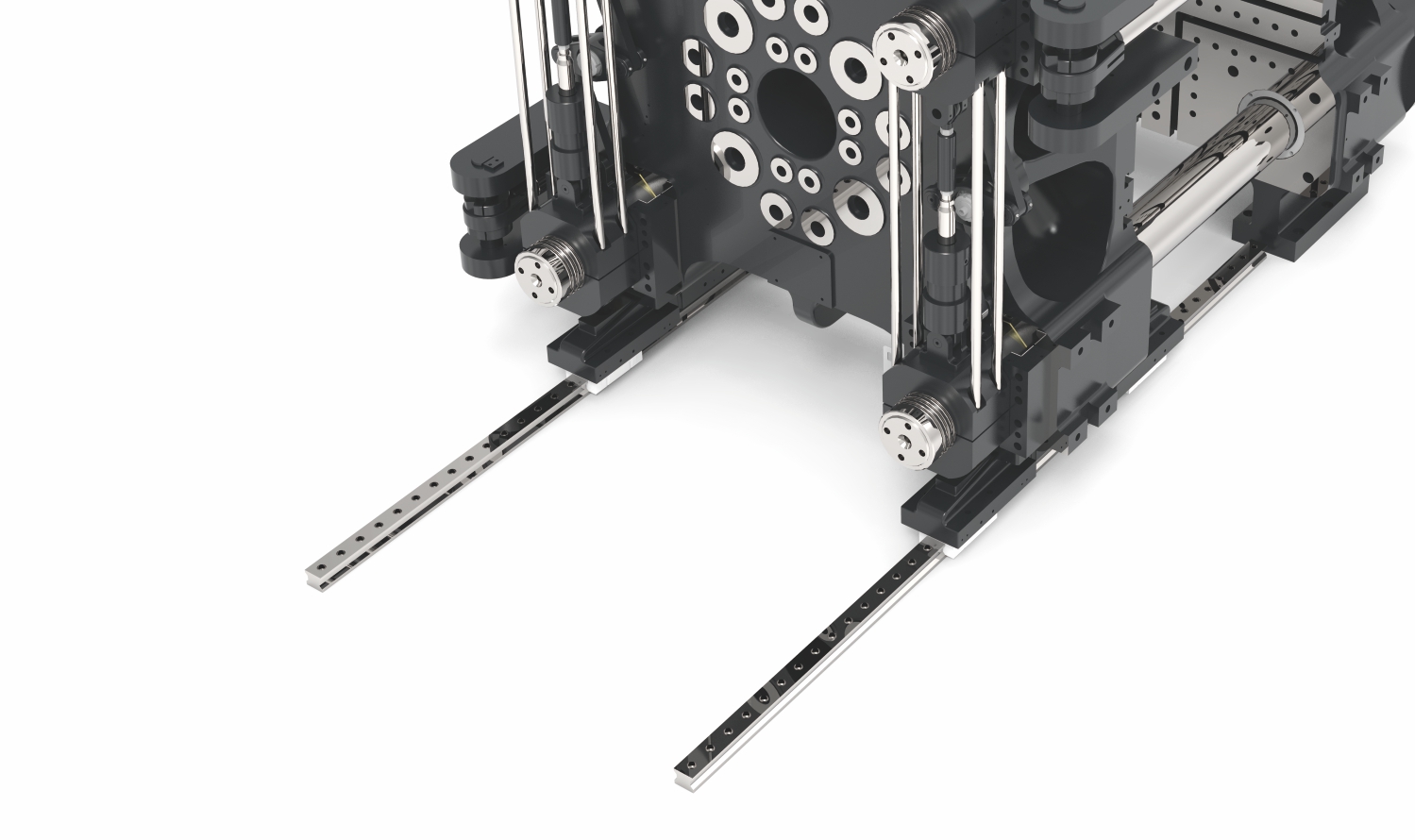

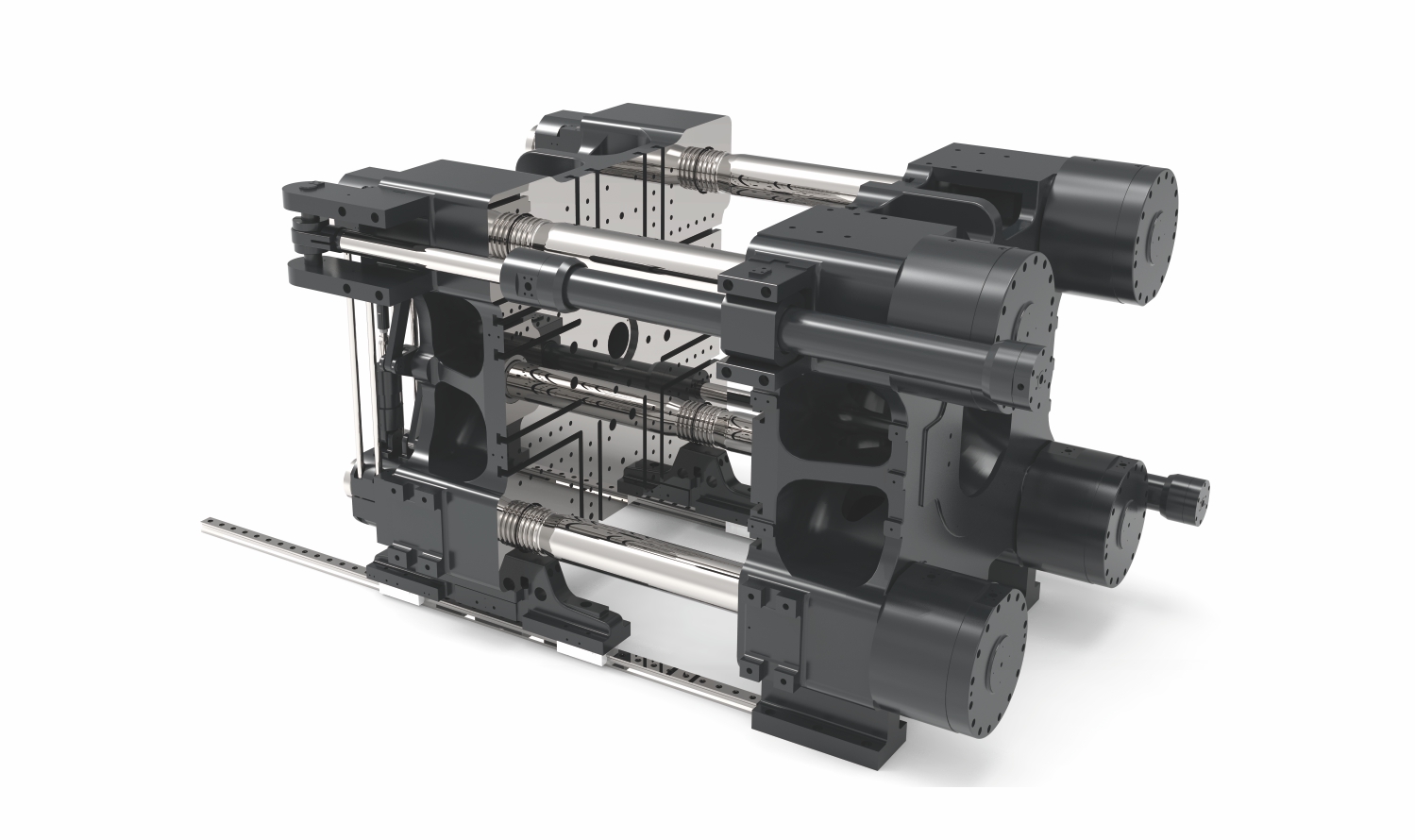

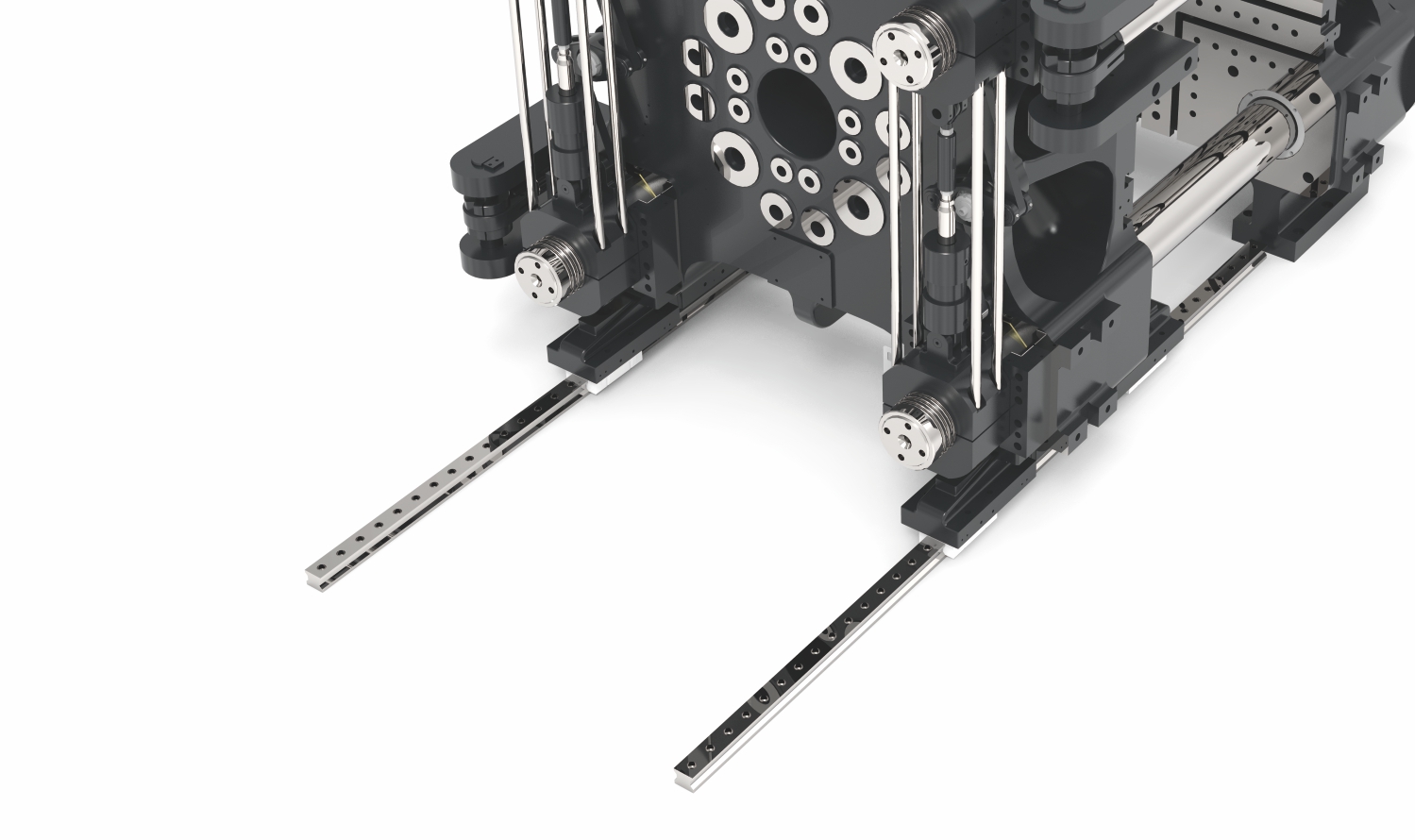

High-precision, high-strength linear rails and sliding feet are used to support the movable template to ensure high parallelism of the template and accurate repeated positioning; the low resistance and low energy consumption of the linear rails can make the opening and closing of the mold smoother and faster, while eliminating the problem of lubricating oil splashing, thus making the entire machine run more smoothly and quickly.

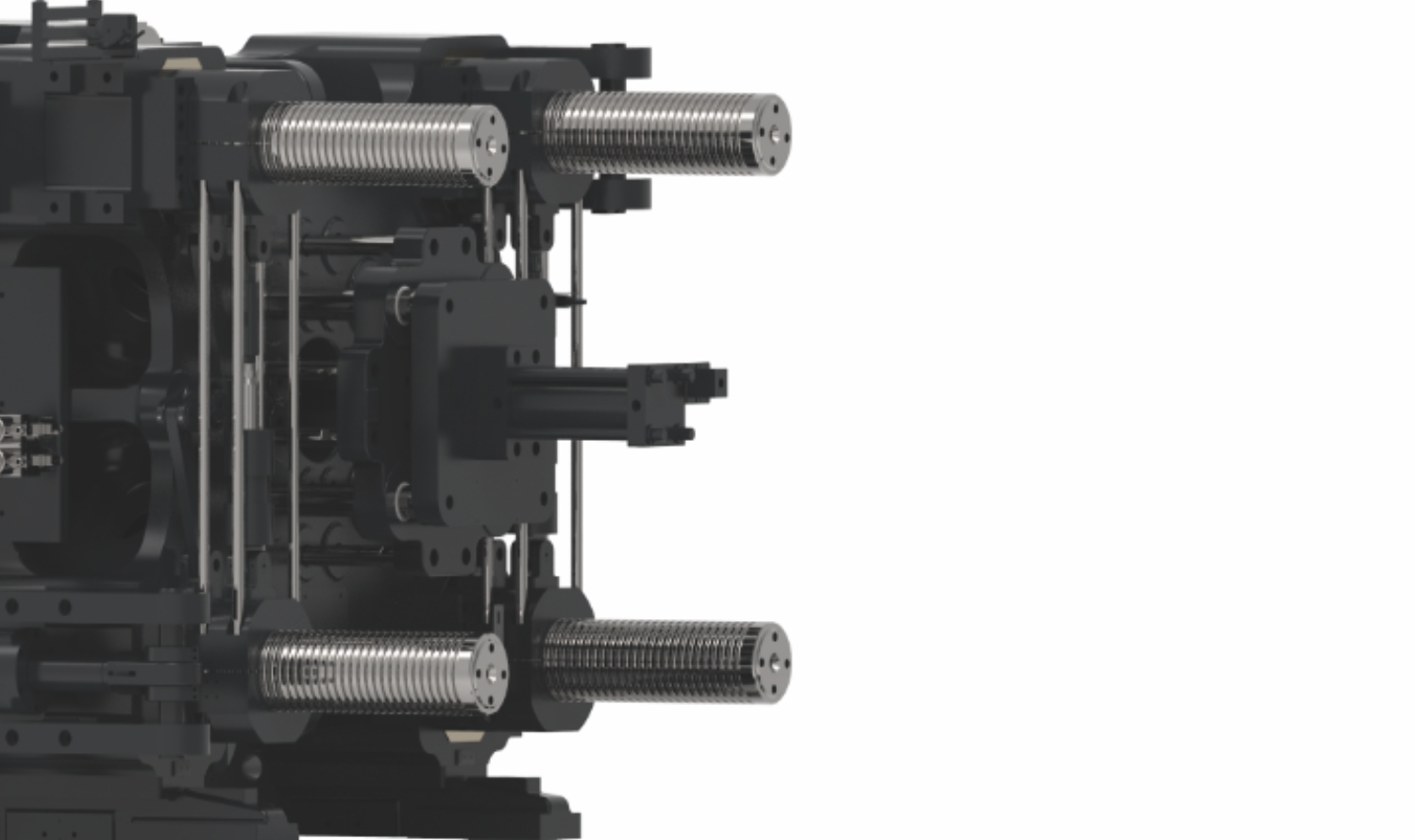

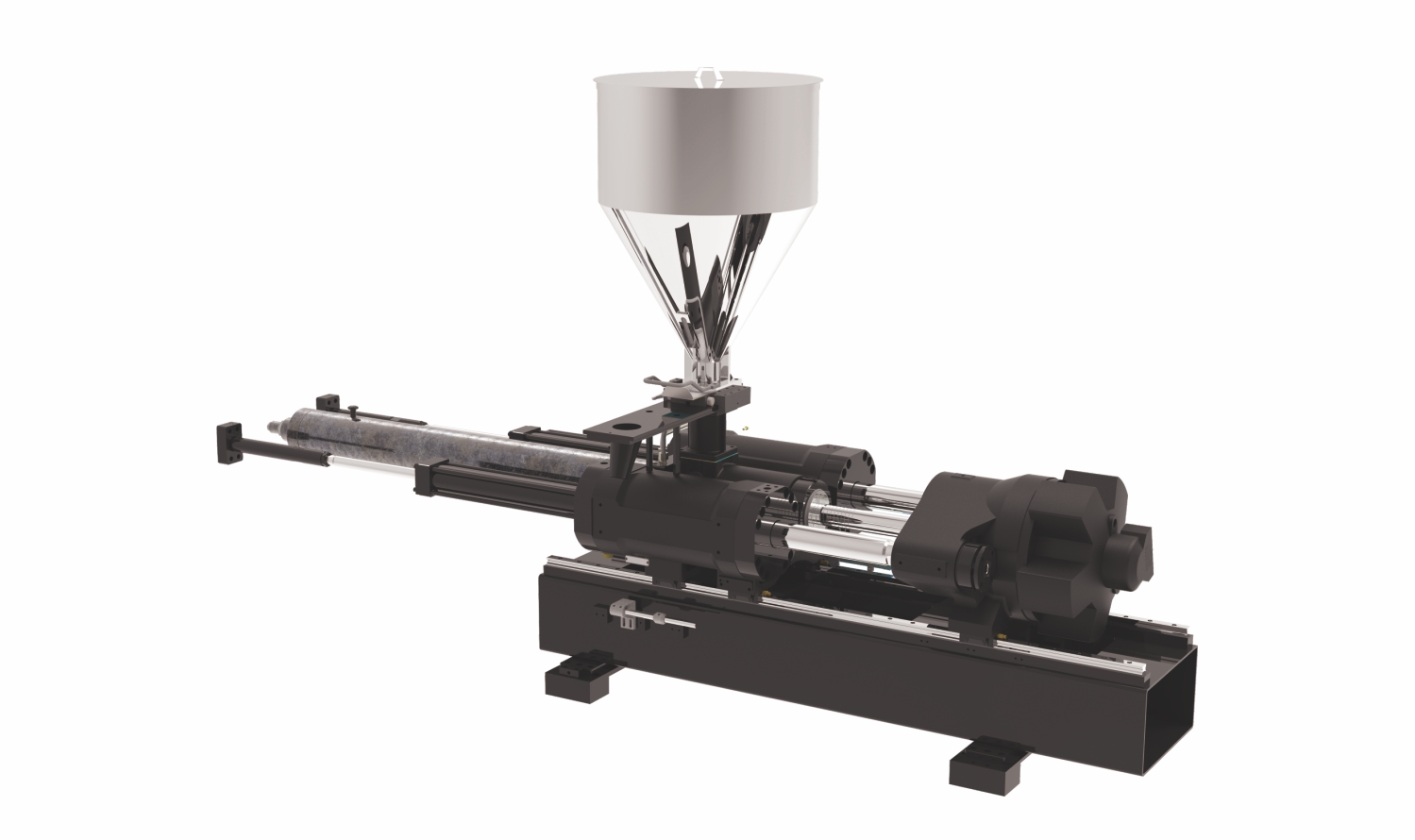

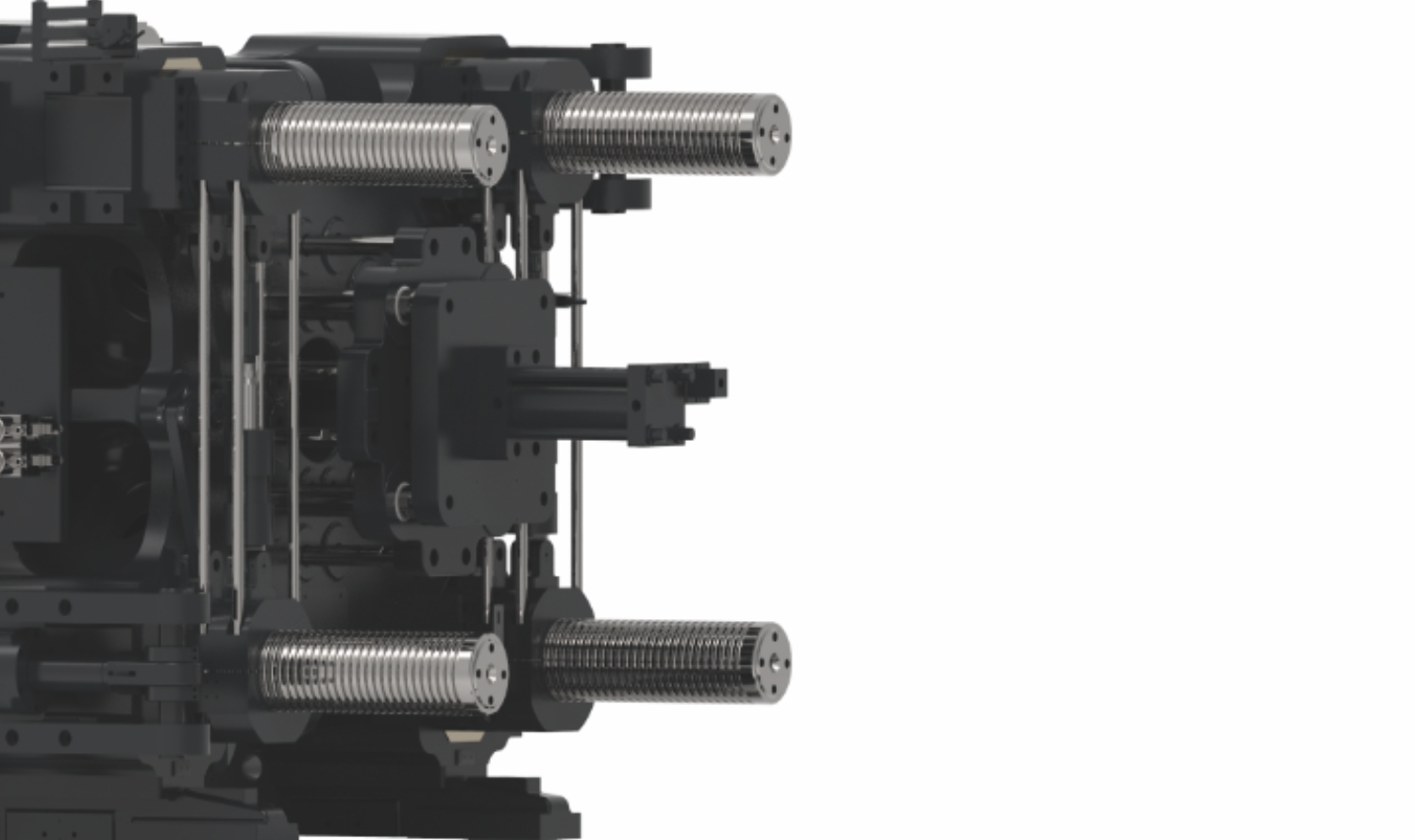

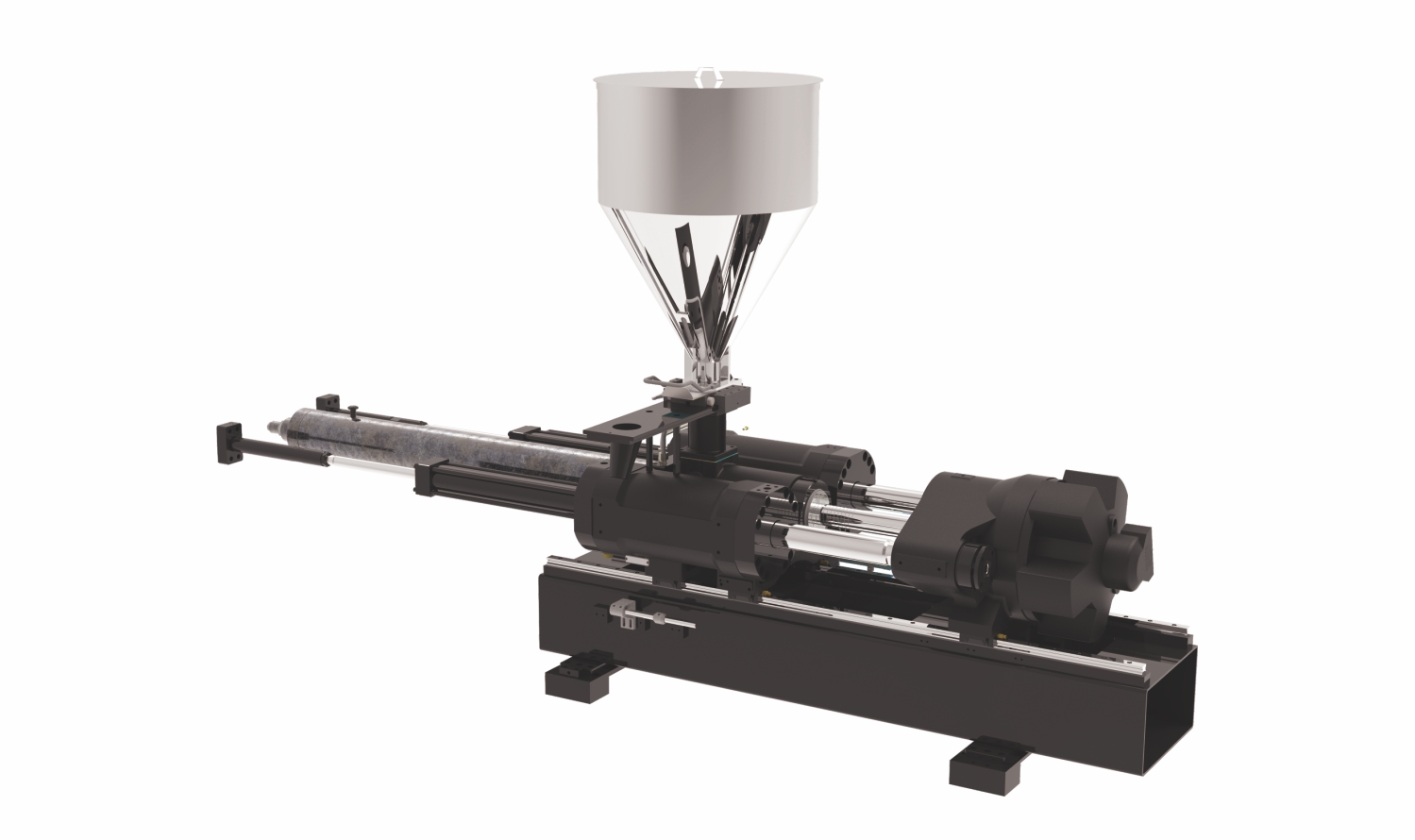

Plasticizing system designed in Germany: the plasticizing efficiency far exceeds the domestic level by more than 20% (common plastics such as ABS, PS, PP, etc.); special plasticizing systems with various complex process requirements and various application requirements can be customized; the screw length-to-diameter ratio of all models A\B\C adopts 23:1 to ensure that each type of screw can achieve the best plasticizing effect and efficiency.

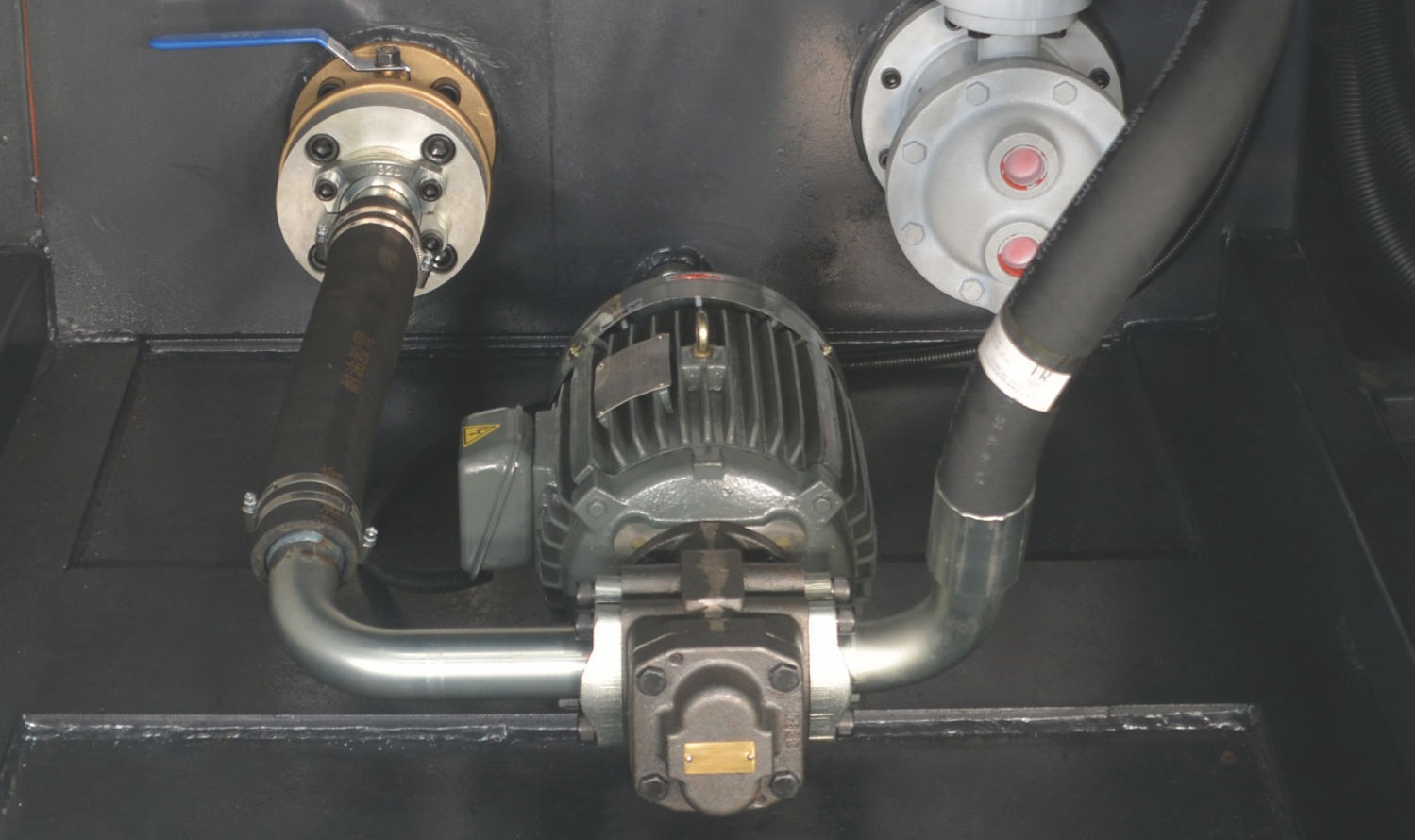

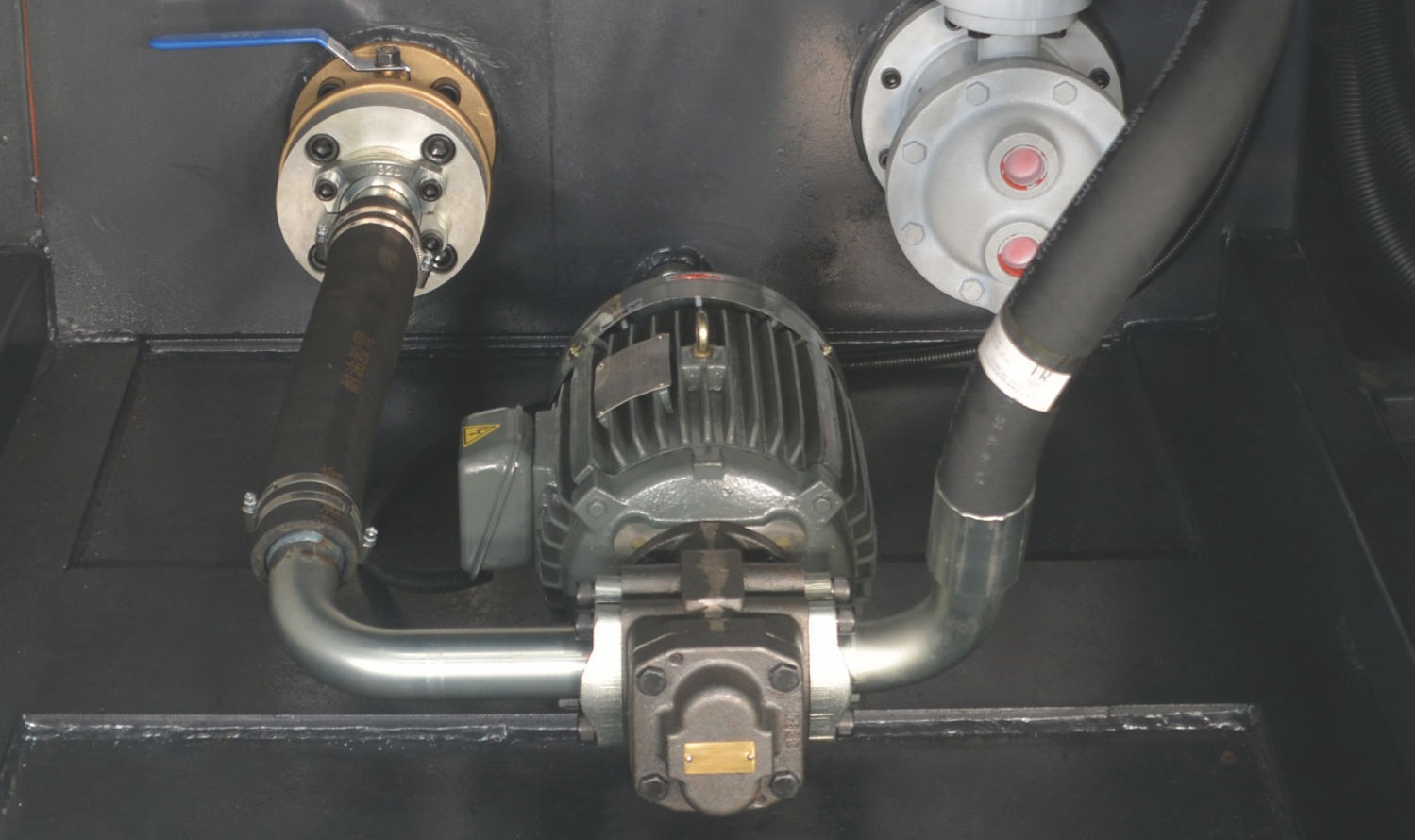

The motor is directly driven, efficient and energy-saving; closed-loop control, fast and accurate; left and right independent control, stable and reliable; easy maintenance, clean and stain-free.

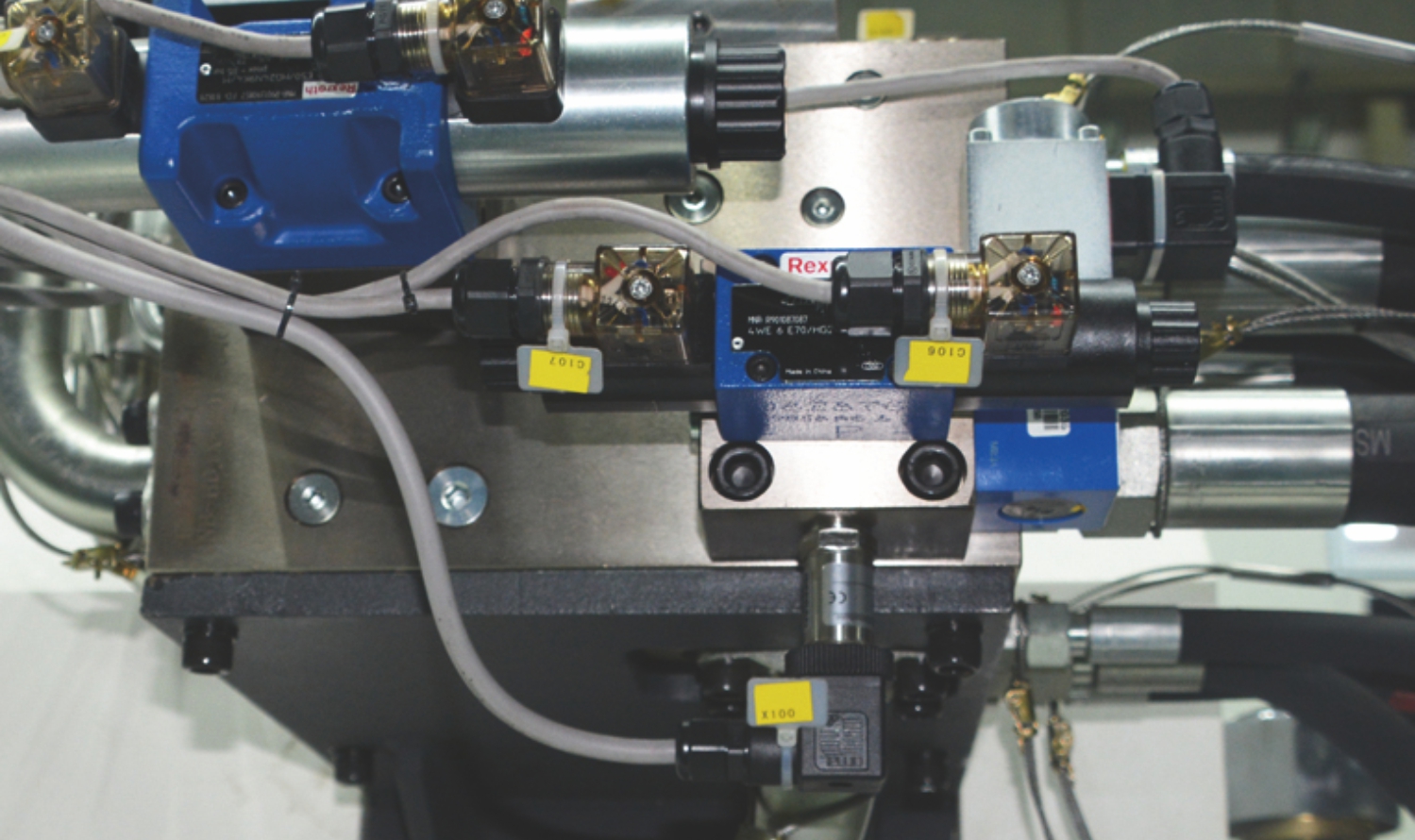

Mechanical operation actions are completed simultaneously to improve efficiency.

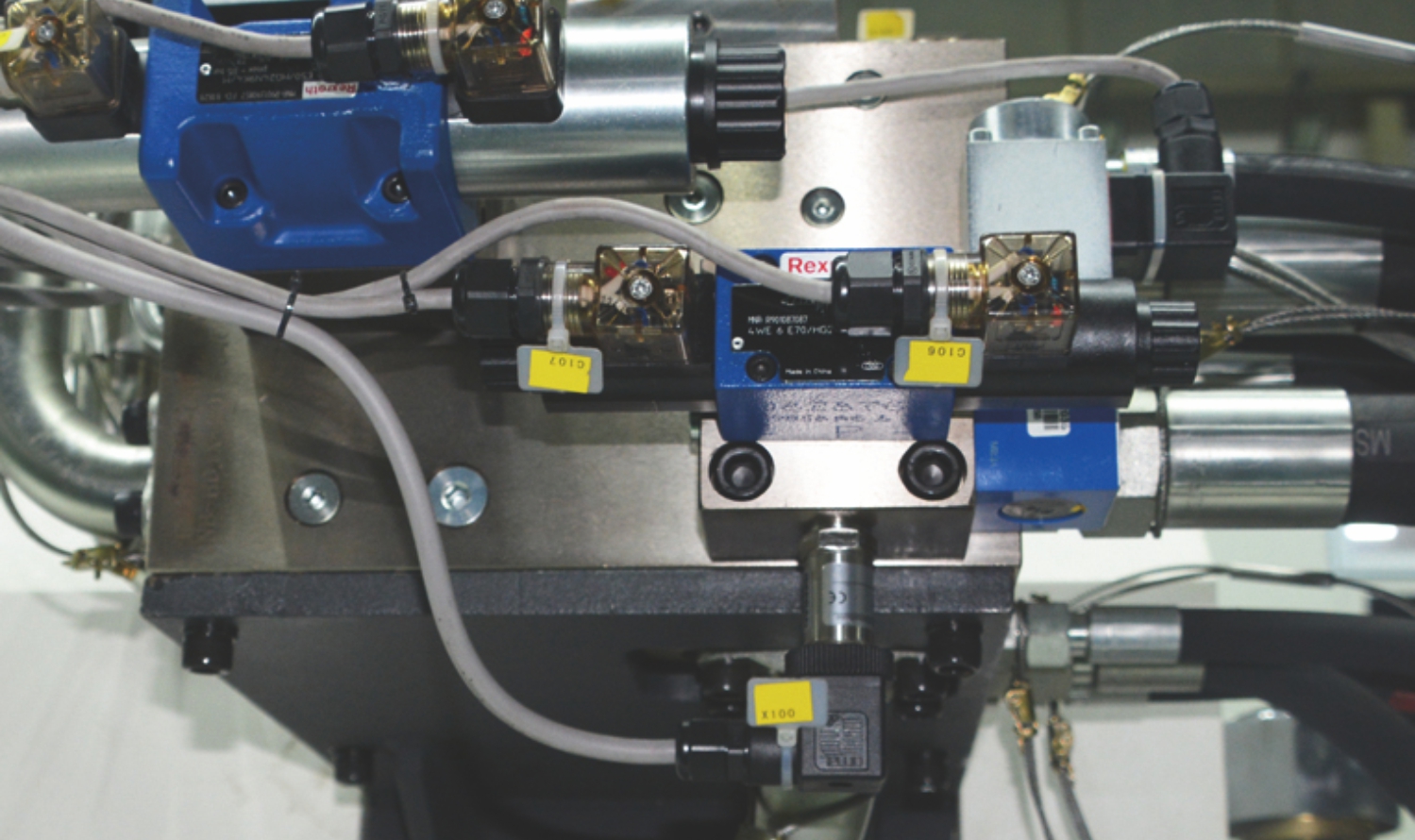

The unique injection cylinder design brings the oil return resistance close to zero. At the same time, combined with the injection platform structure of the linear slide rail, it effectively reduces the friction of the injection part, greatly improving the control accuracy and stability of the injection unit, far exceeding other domestic brands.

The variable-pitch screw thread brake nut design is adopted to make the screw threads evenly stressed and ensure a long service life of the tie rod.

It is compact and takes up less space. The oil temperature in the hydraulic pressure circuit of the whole machine is constant and is not affected by the mold opening and closing cycle time, other structural units or external factors. The machine runs smoothly; at the same time, the service life of the oil is extended.

Incorporating the temperature of the unloading port into the closed-loop control of the temperature unit improves the efficiency and accuracy of the entire injection molding unit, while avoiding the phenomenon of low injection precision caused by clumping and irregularity of the unloading material.

The injection pressure situation is constantly fed back, and the injection curve facilitates customers to monitor and adjust the production process, effectively solving the problem of customers having difficulty in adjusting the production process.