MK series

Wide plate multi-component injection molding machine

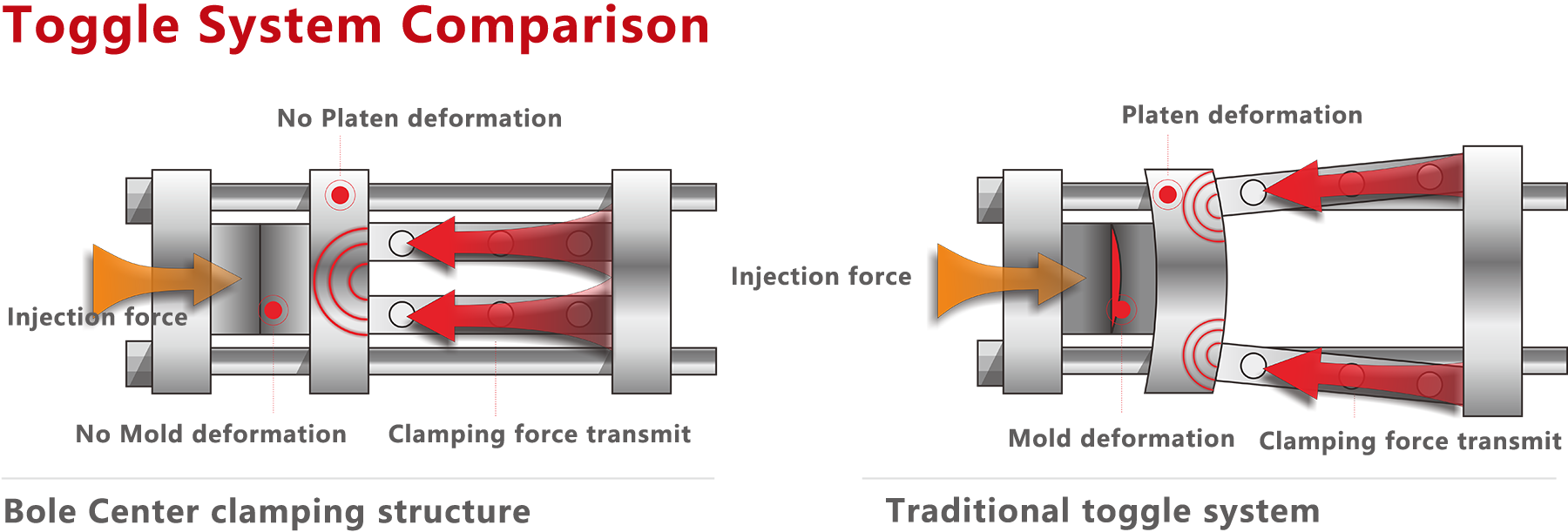

Bole's multi-component three-plate injection molding machine

meets the demand for personalized products and beautiful appearance in industries such as automobiles, home appliances, daily necessities, food packaging, toys and other industries. With its excellent performance and excellent quality, it helps users improve their core competitiveness.

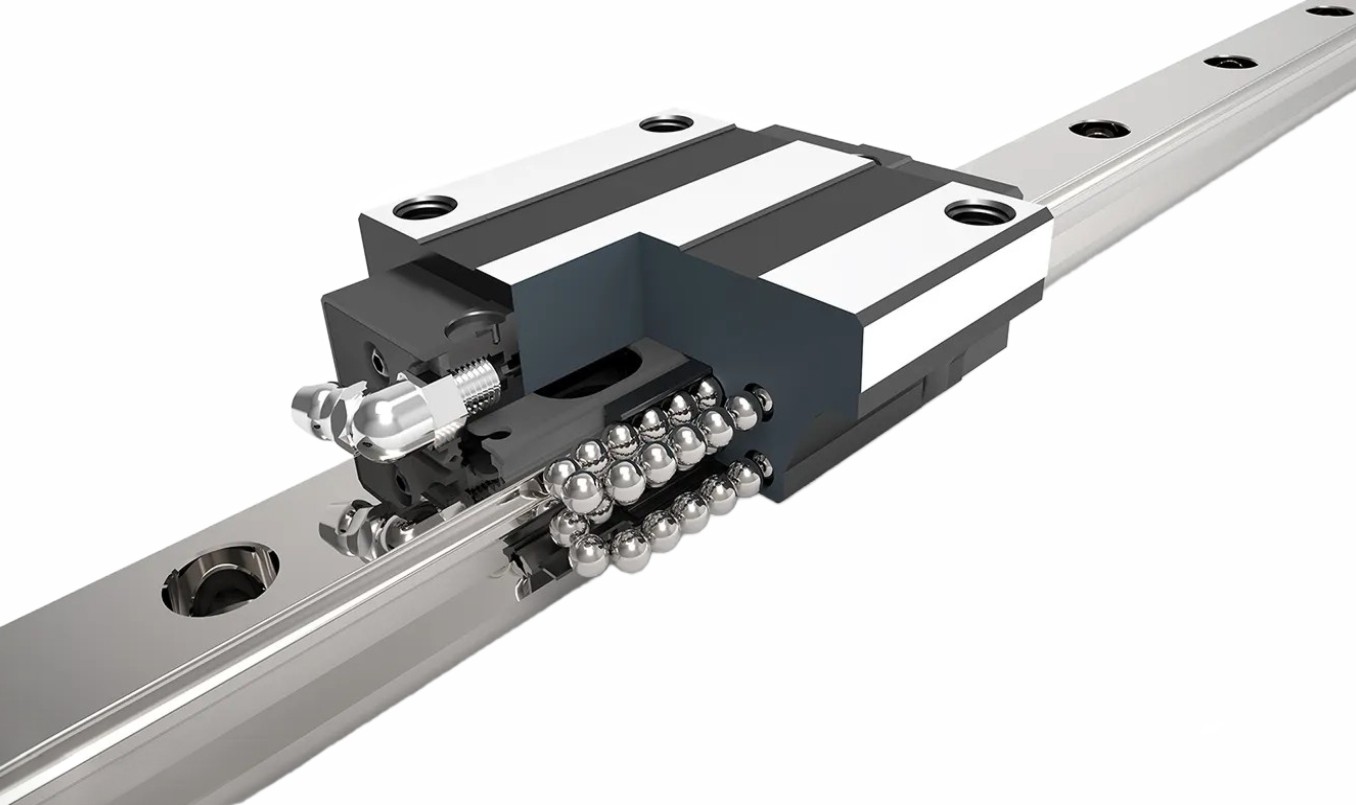

Mold clamping adopts linear guide rail

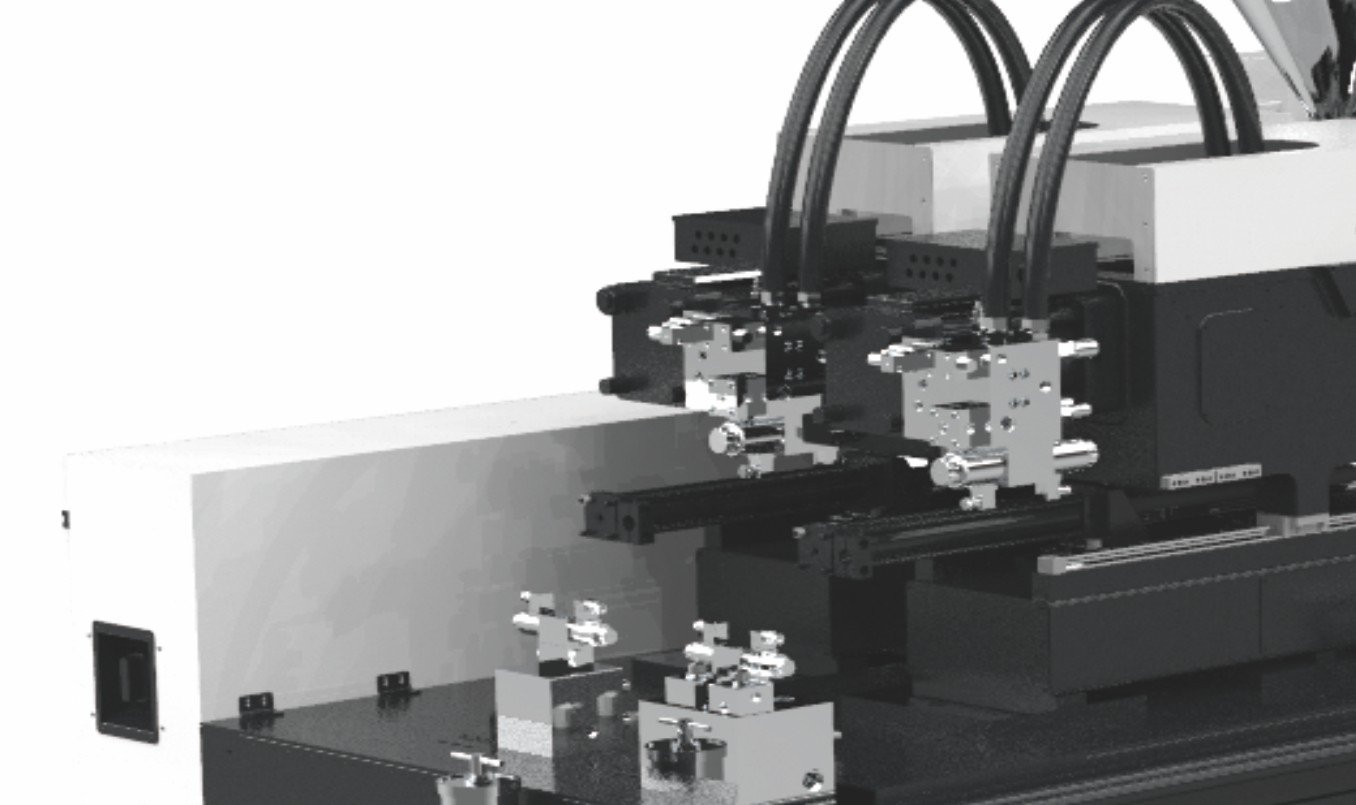

Wide plate turntable comes standard with servo turntable system

Efficient hydraulic system

Control system

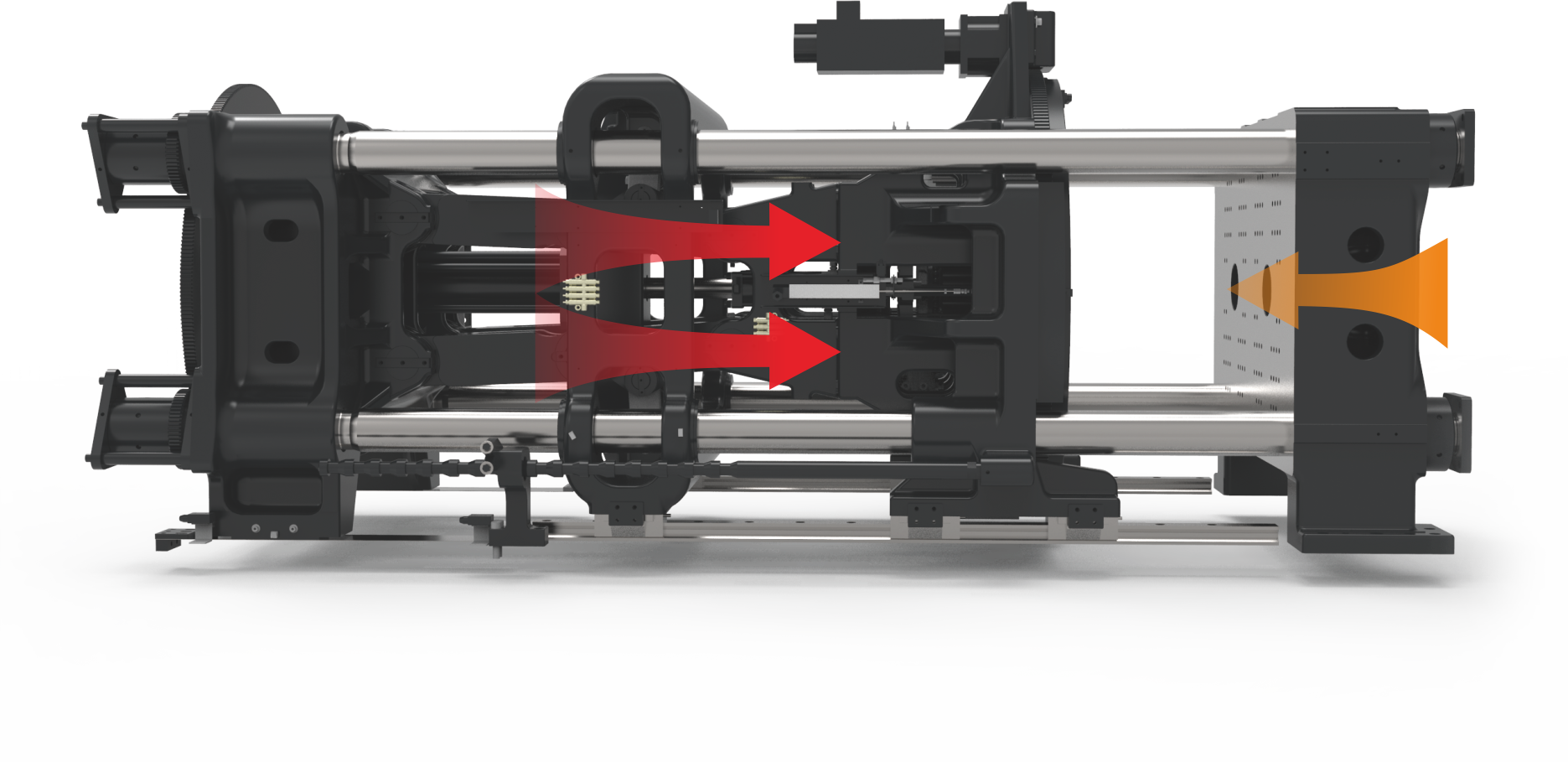

Single cylinder injection structure