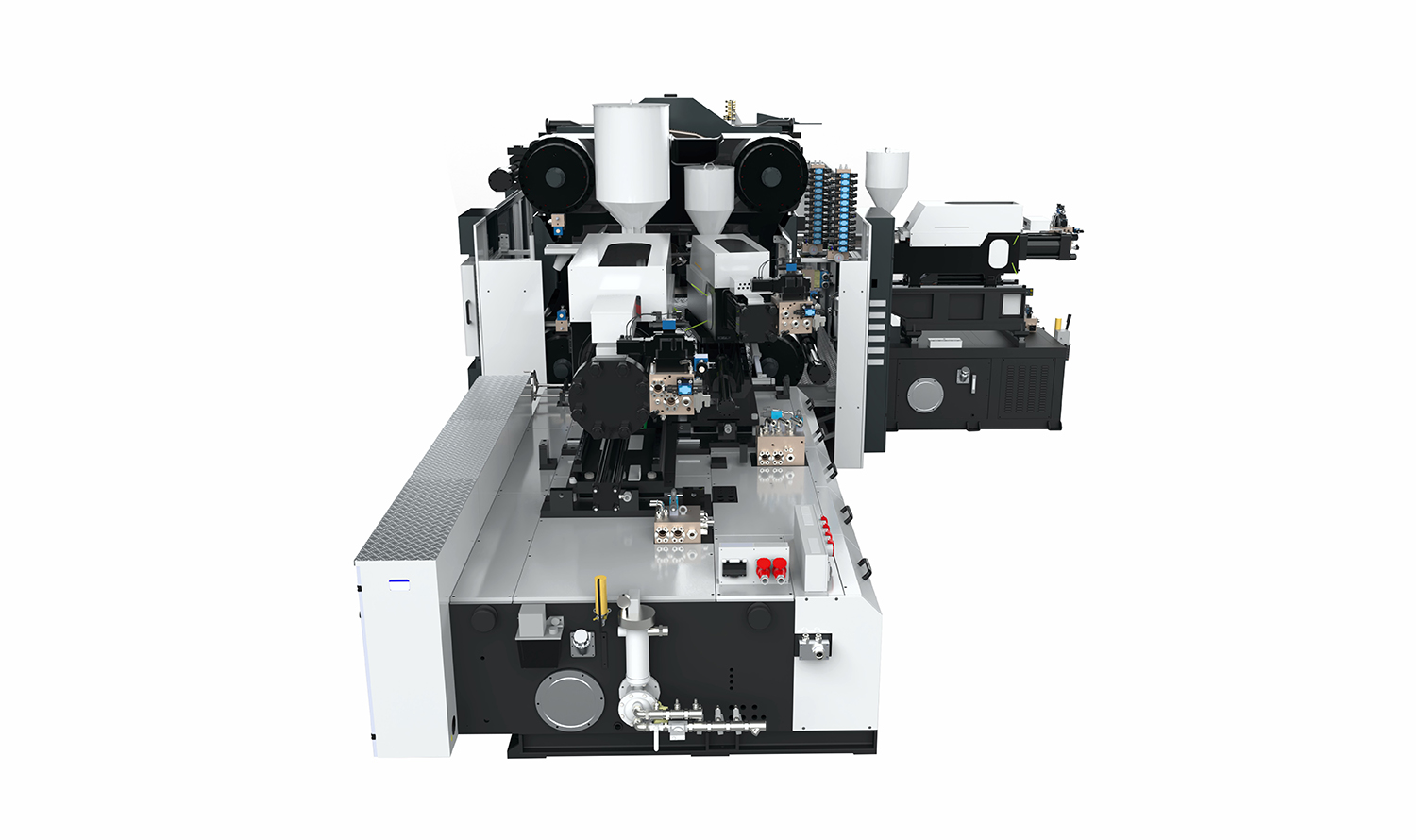

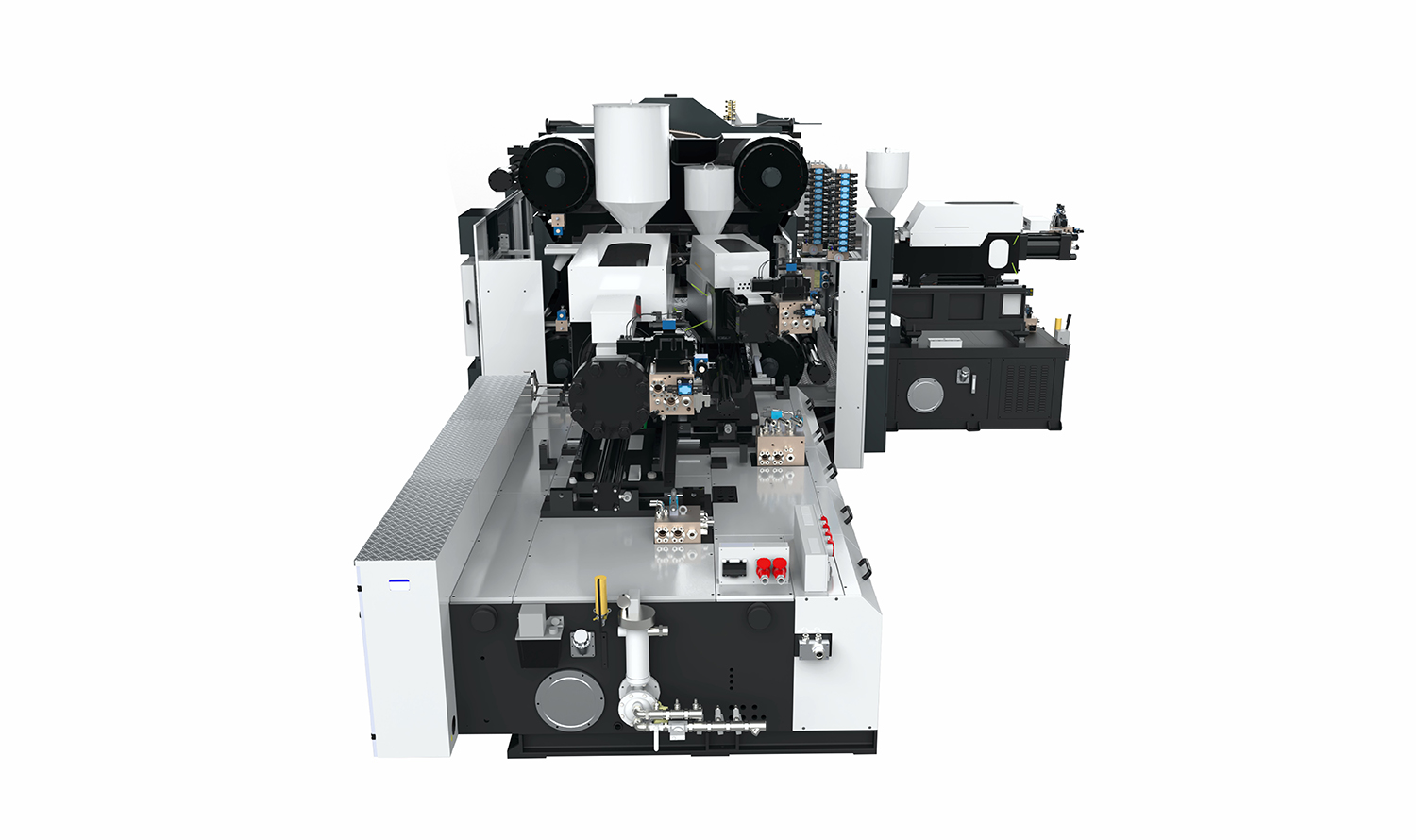

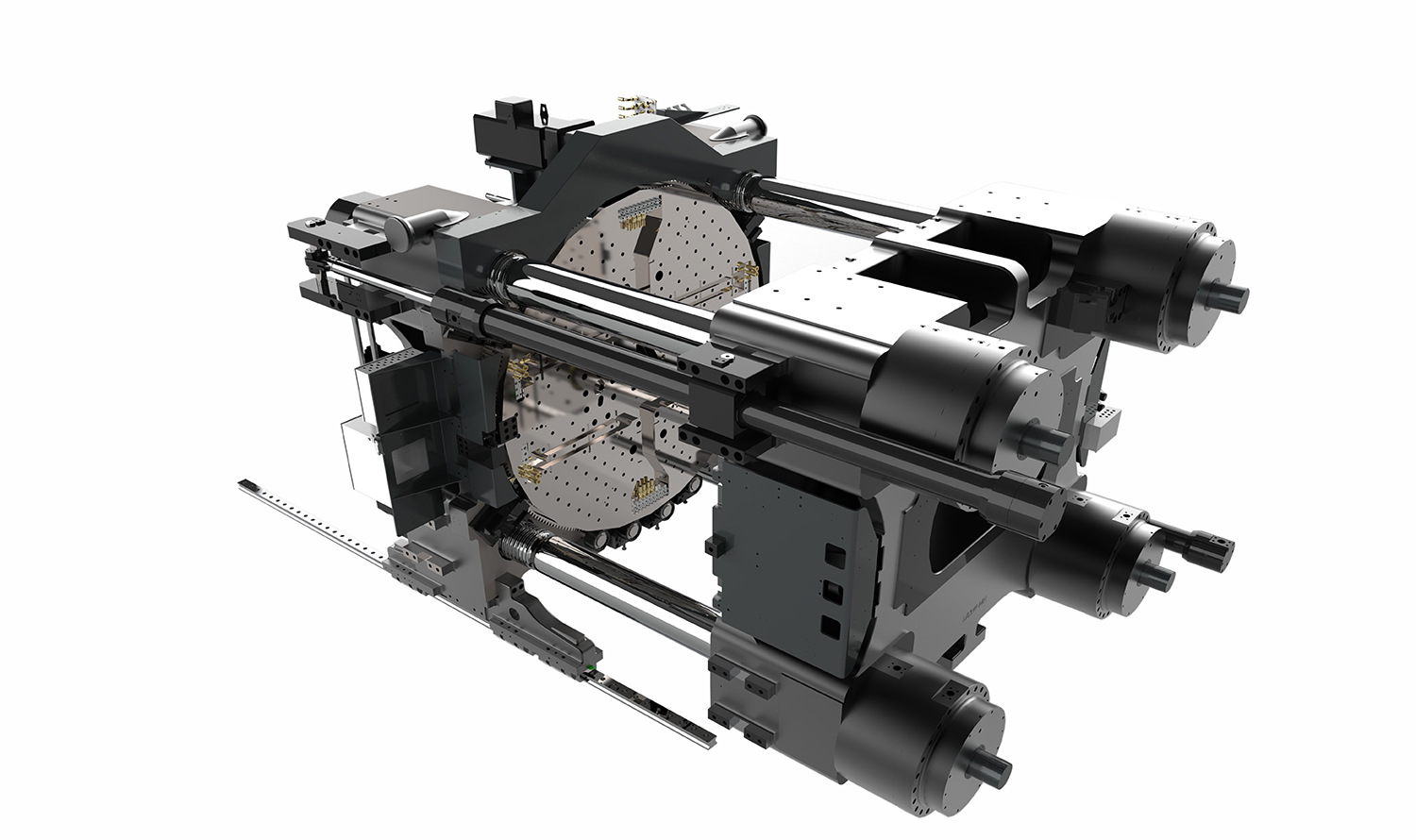

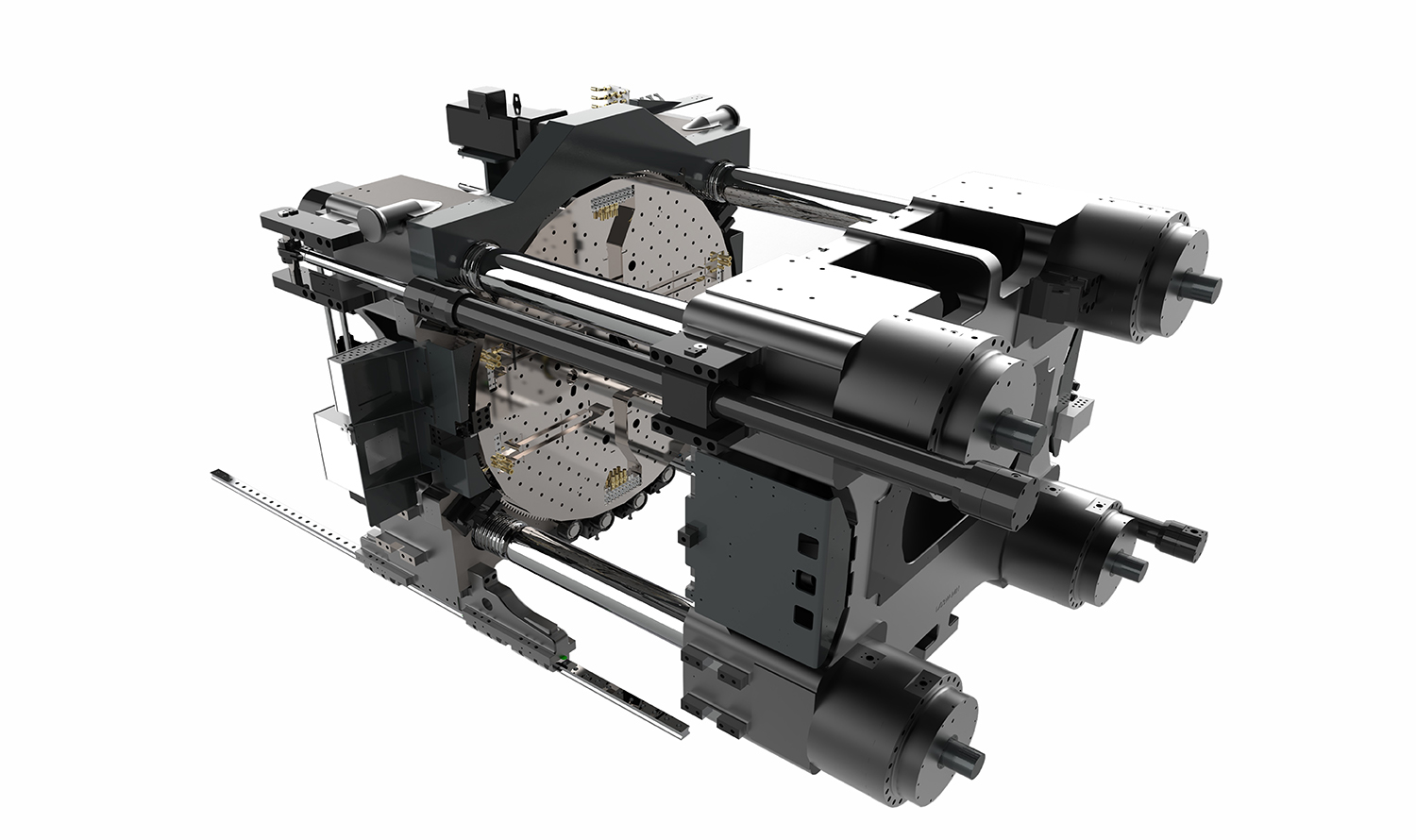

The template adopts a large turntable design, which has a large mold capacity and a wide range of mold applications; it can meet customer customization and has diverse functions. The turntable rotates quickly, stably, and has accurate positioning; it is easy to operate and there is no problem of changes in oil pressure and oil temperature.

The center distance of the mold can be adjusted for diversified movement, and a universal injection table can be installed for the production of three-color products.

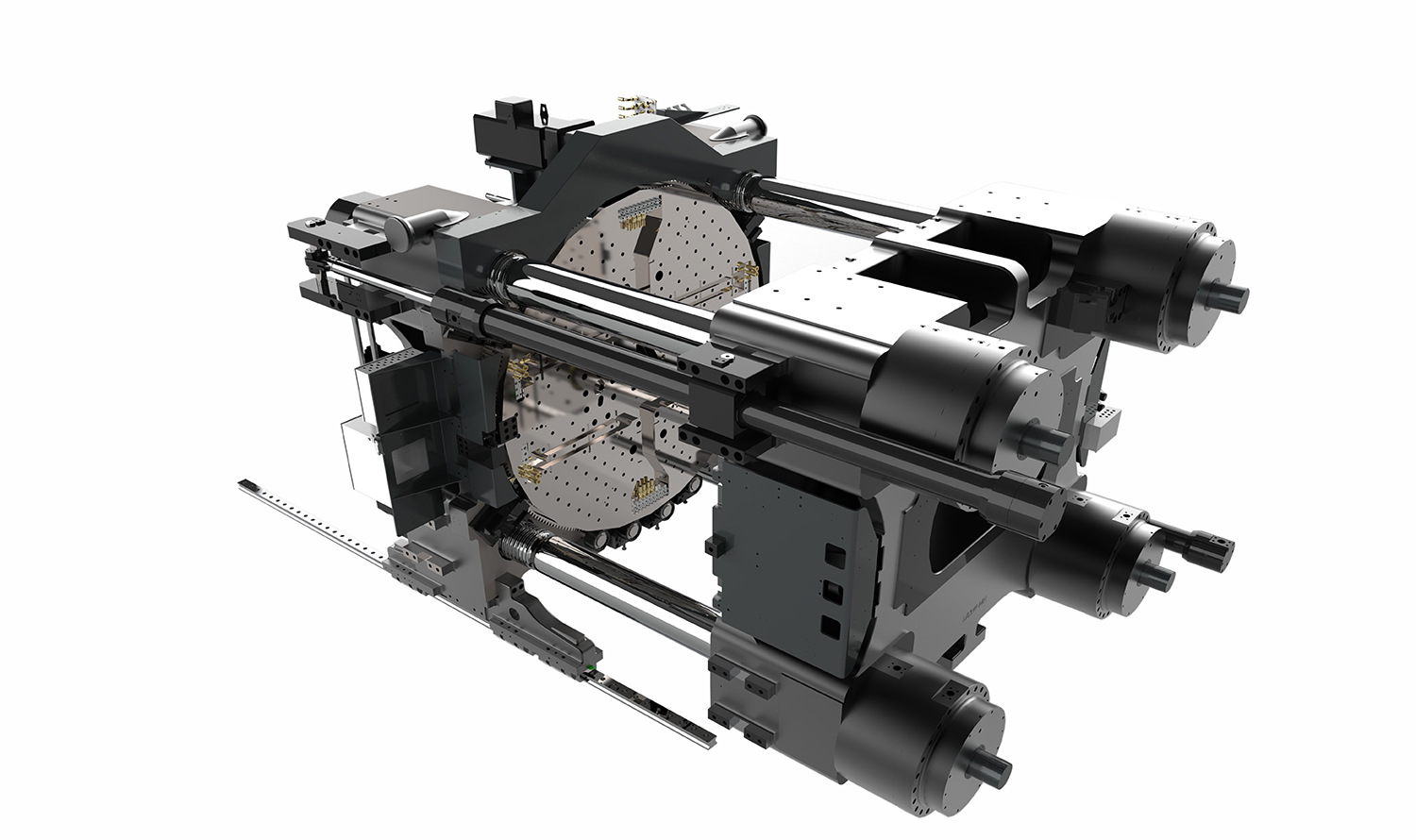

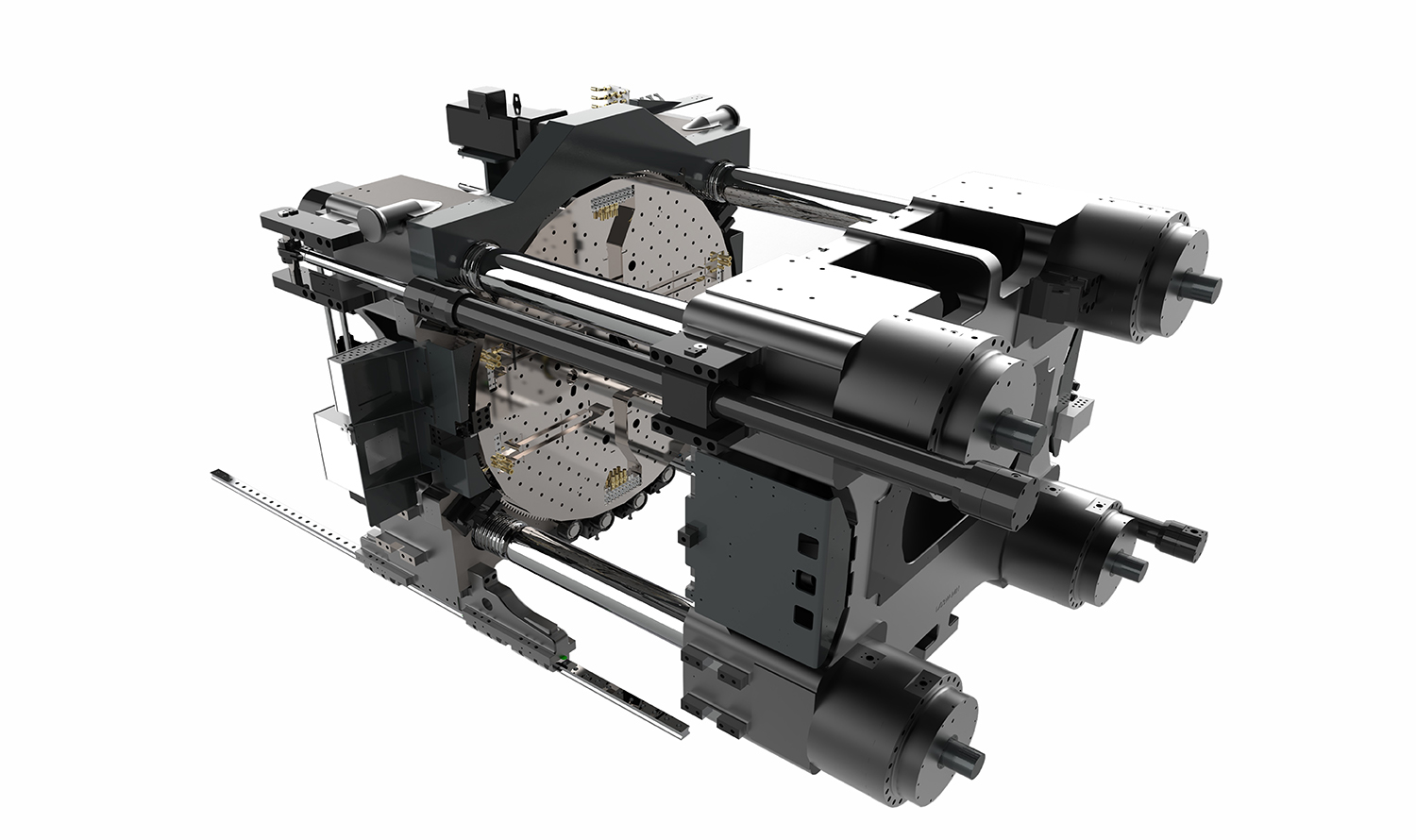

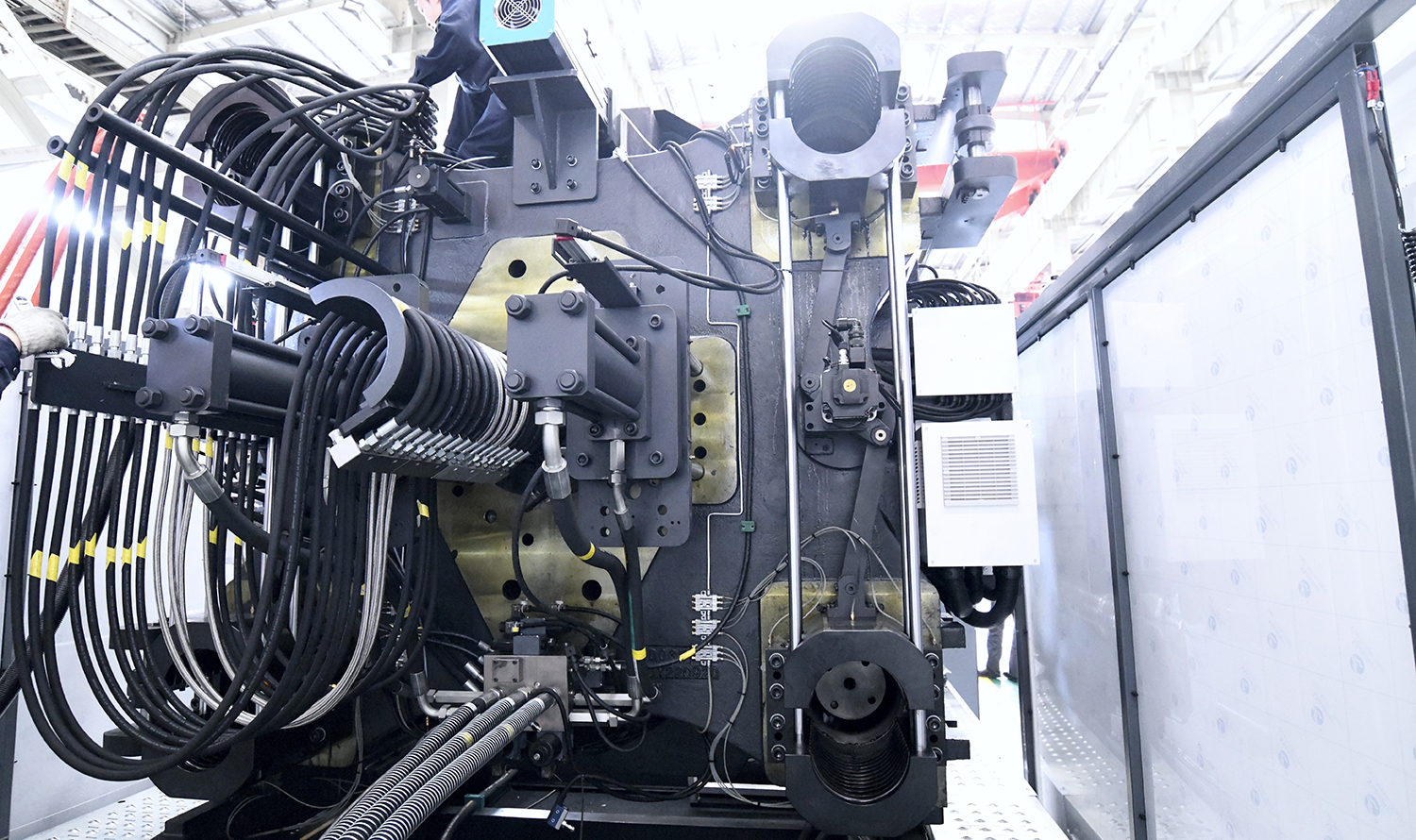

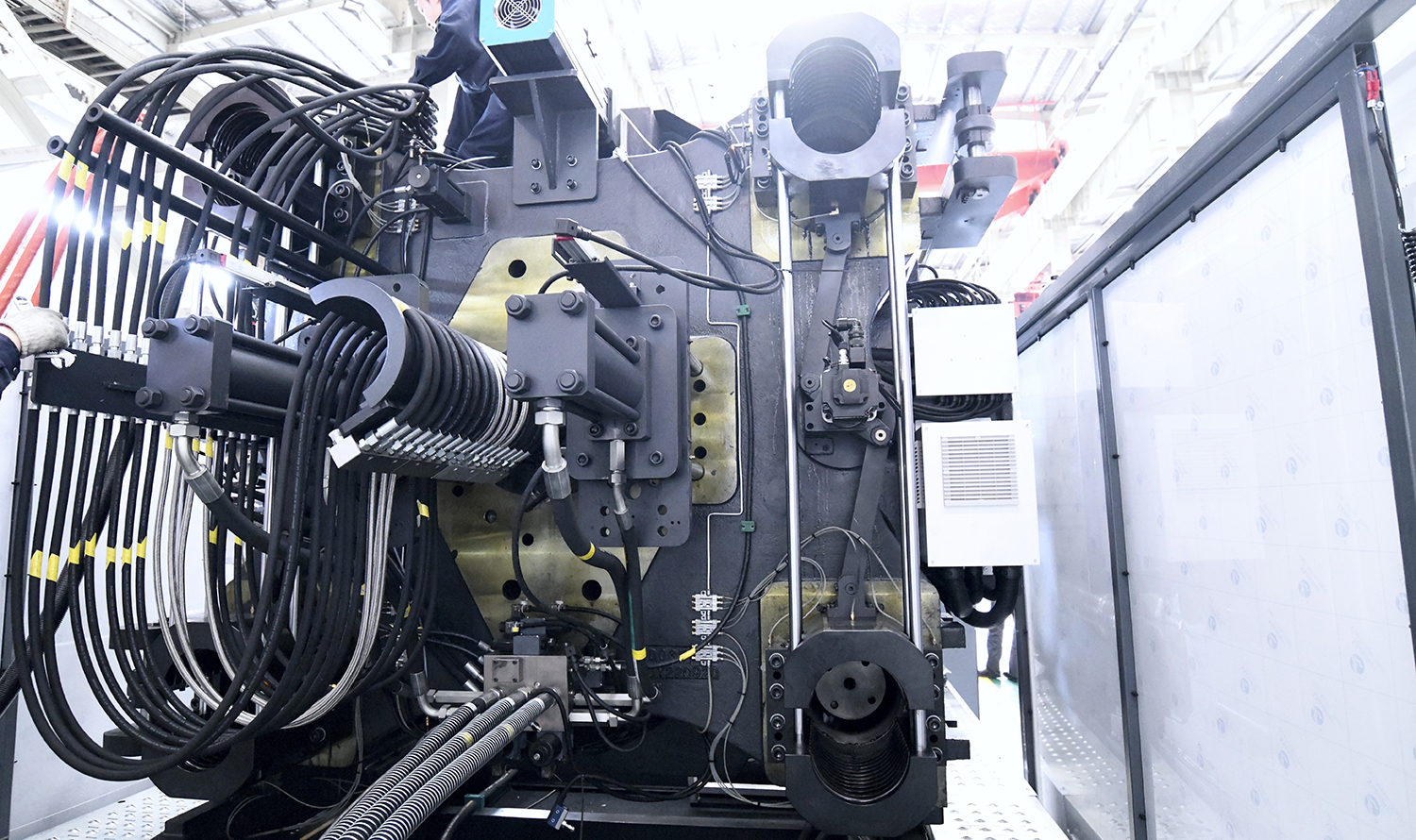

The patented anti-breakage tie rod design adopts an integral structure, with a smooth transition from the high-pressure piston to the tie rod with large rounded corners. Compared with the traditional threaded connection structure, it eliminates stress concentration points and increases the strength by more than 5 times. This ensures the long-term stability of the machine.

The mold clamping uses high-precision, high-strength linear guide rails with sliding feet to support the moving template. Compared with traditional sliding feet, the linear rail resistance is small (sliding friction coefficient 0.2, linear rail 0.004), making the opening and closing of the mold smoother, higher control accuracy, and lower energy consumption; linear rail rolling friction and less lubrication can avoid lubricant splashing problems, making the whole machine cleaner and tidier! The high-strength linear guide rails eliminate mold deflection and tilt problems during the template movement, effectively protecting the mold from damage.

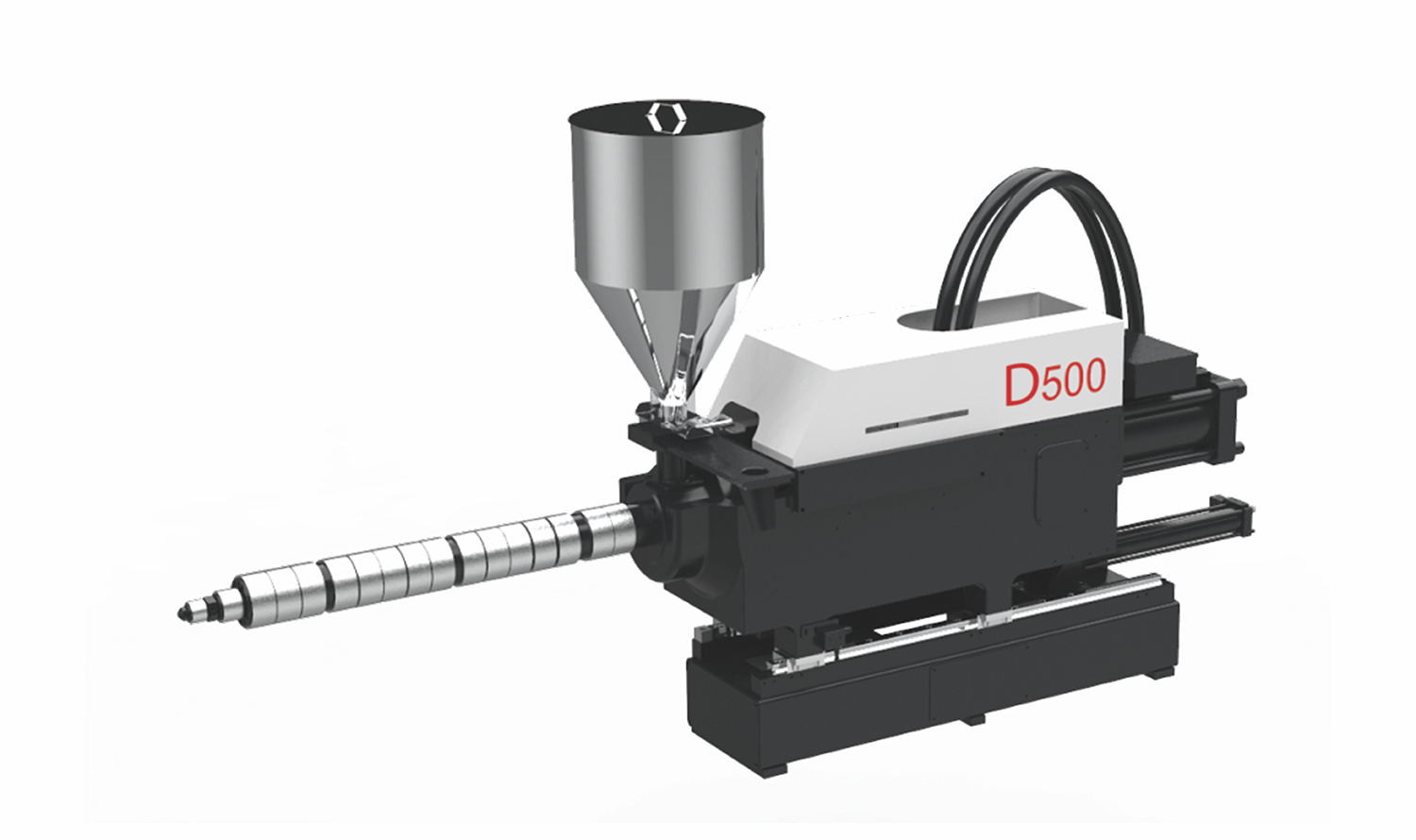

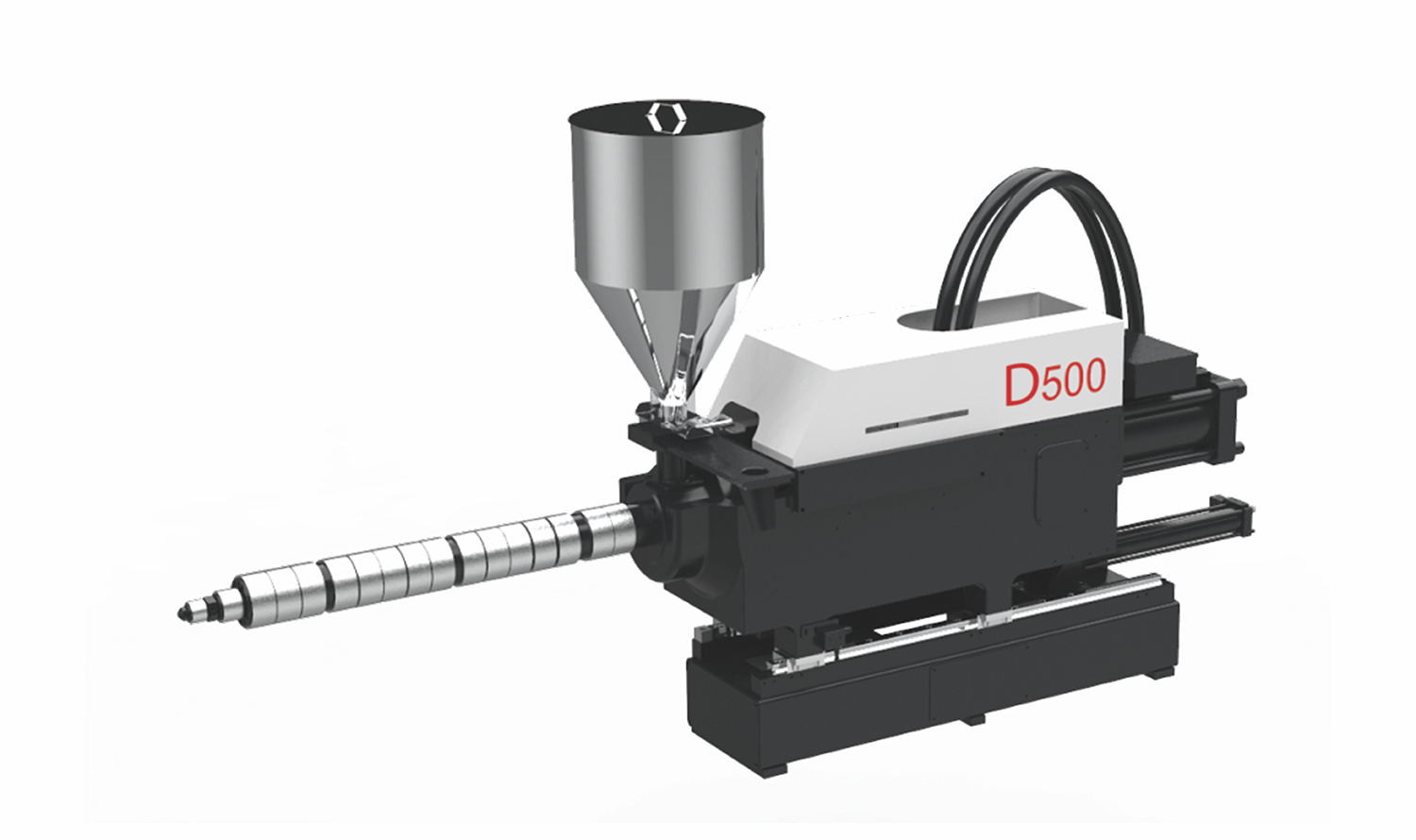

The injection part adopts a special single-cylinder structure. The injection piston does not rotate with the screw, and there is no risk of oil leakage.

Motor direct drive, high efficiency and energy saving, closed-loop control, fast and accurate, left and right independent control, stable and reliable; easy maintenance, clean and stain-free.

The scalability is strong. By adding plug-in 1/0 modules, more input and output points can be achieved to meet more customer needs. The control response speed is fast, up to 0.5ms. The temperature accuracy is high, the best can reach ±0.2℃.

Supports a variety of injection molding production sequences and expansions to meet users' applications in different scenarios. The 110 modules are connected via a real-time Ethercat bus with periodic scanning up to 0.5ms. Real-time injection curve display allows users to effectively adjust the injection molding process. Supports OPC protocol to meet the needs of users with MES system applications. Intelligent multi-point PID precise temperature control.