·Save materials, save electricity, save machines and save maintenance;

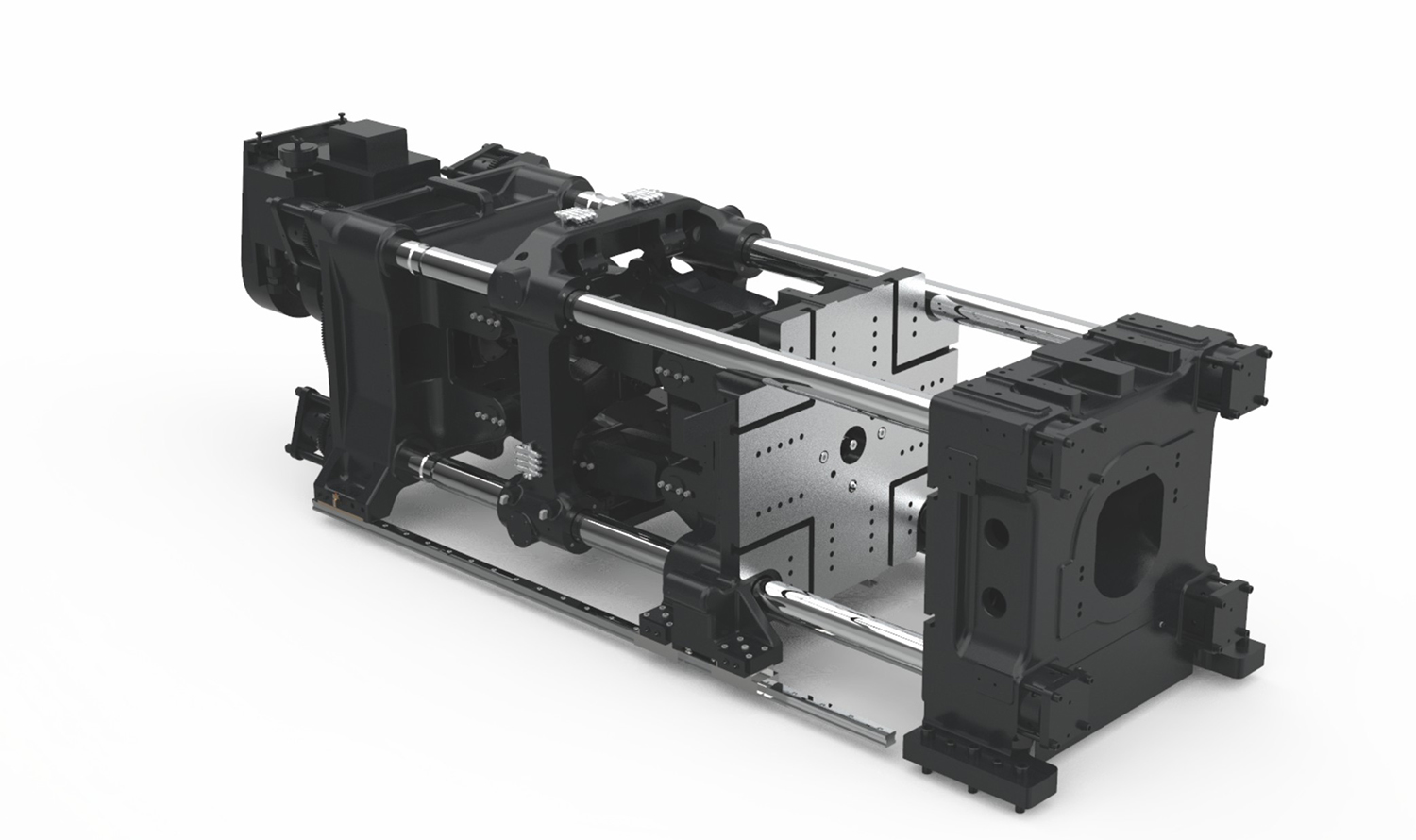

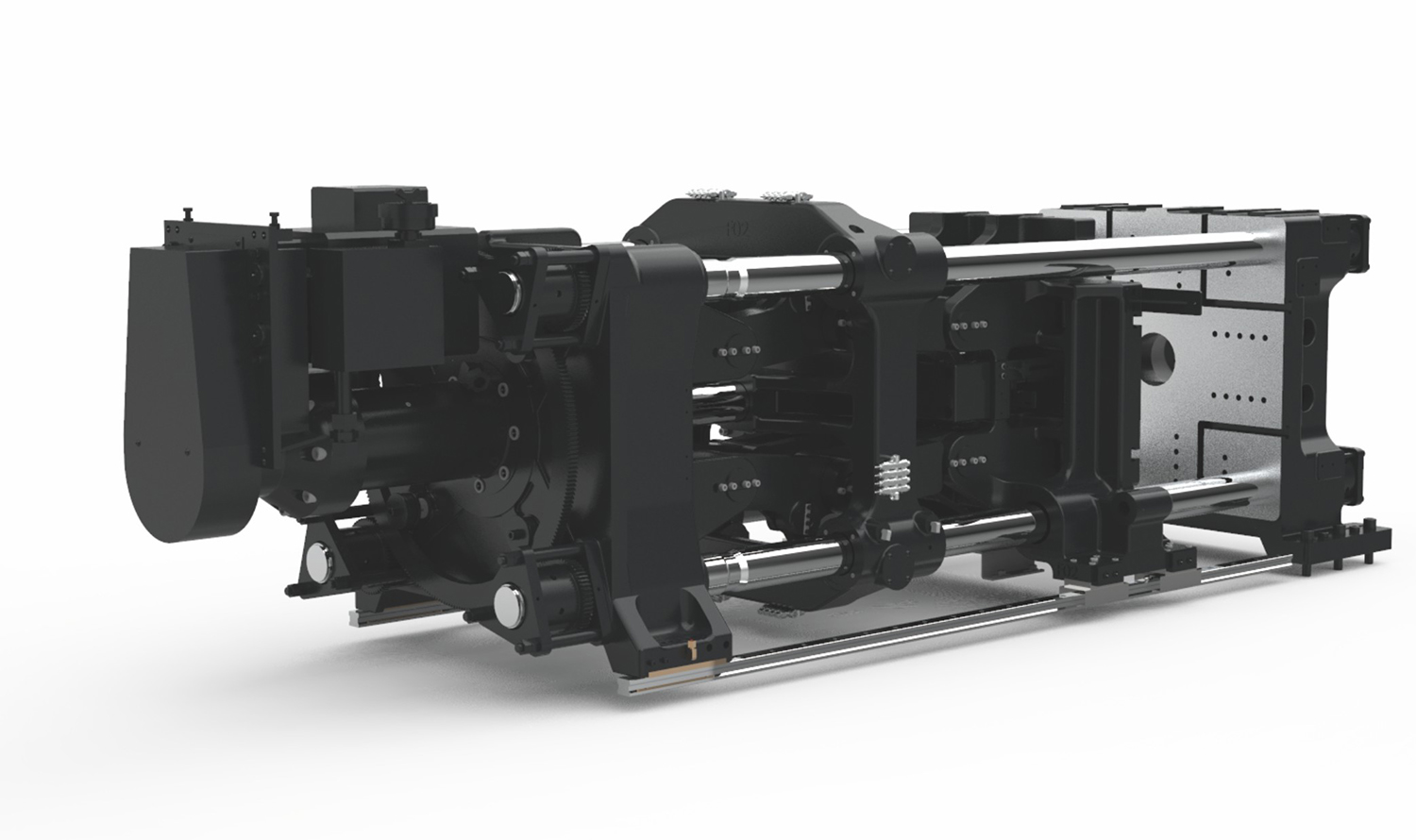

·Accurate position, speed, mold and parallelism; large distance between tie rods and large mold opening stroke;

·No oil pollution in the product area

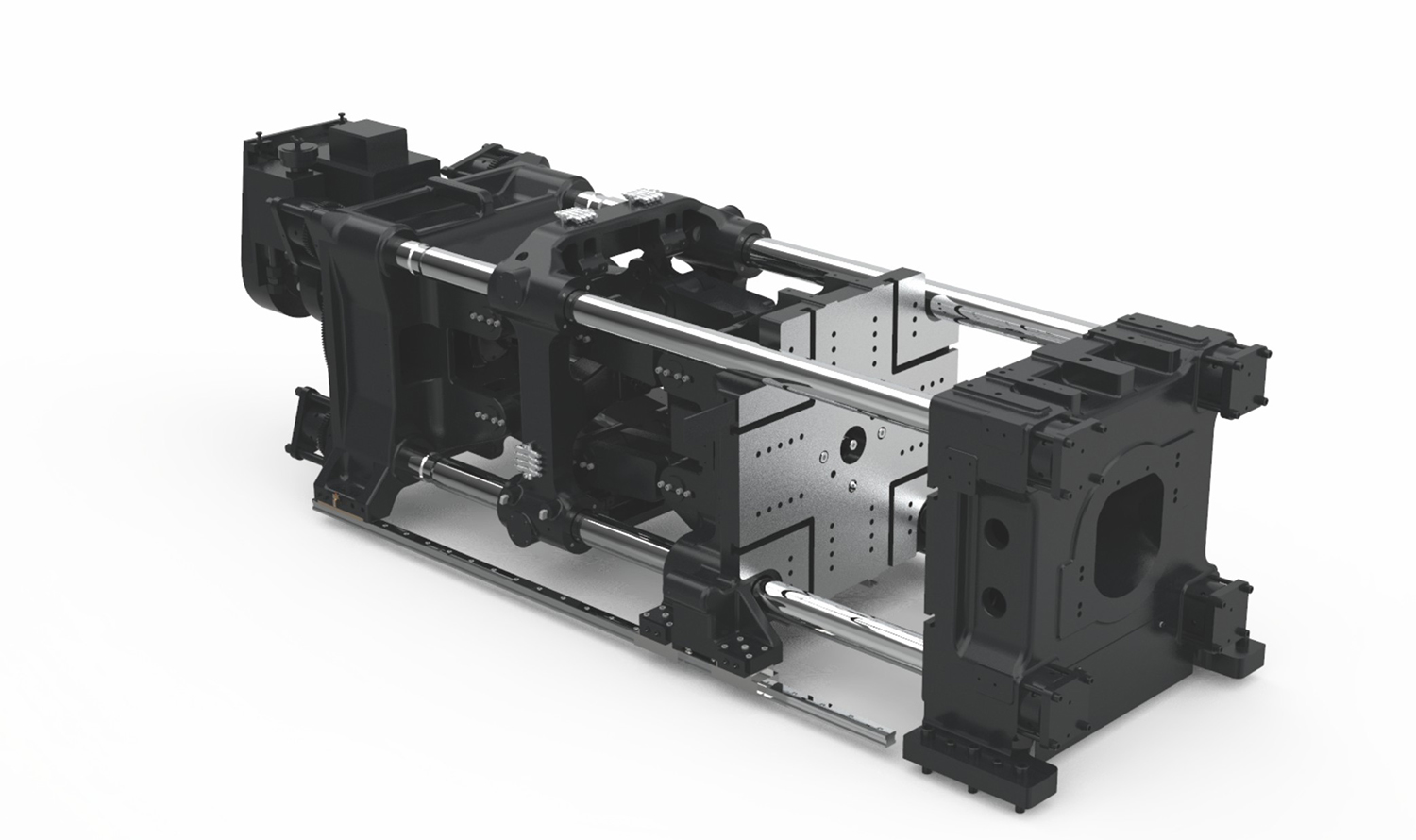

·More accurate mold opening and closing control, the template position repeatability can be as high as 0.01 level, especially suitable for in-mold labeling and robot automation

·More flexible motion control curve, the mold opening and closing control is fast and stable;

·More Sensitive and reliable mold protection function;

·Tie rod detachment, no need for lubrication, ensuring clean mold area; no need for copper sleeves, no wear, constant accuracy:

·Better template parallelism, no need for lubrication when moving the template, keeping the product drop area clean.

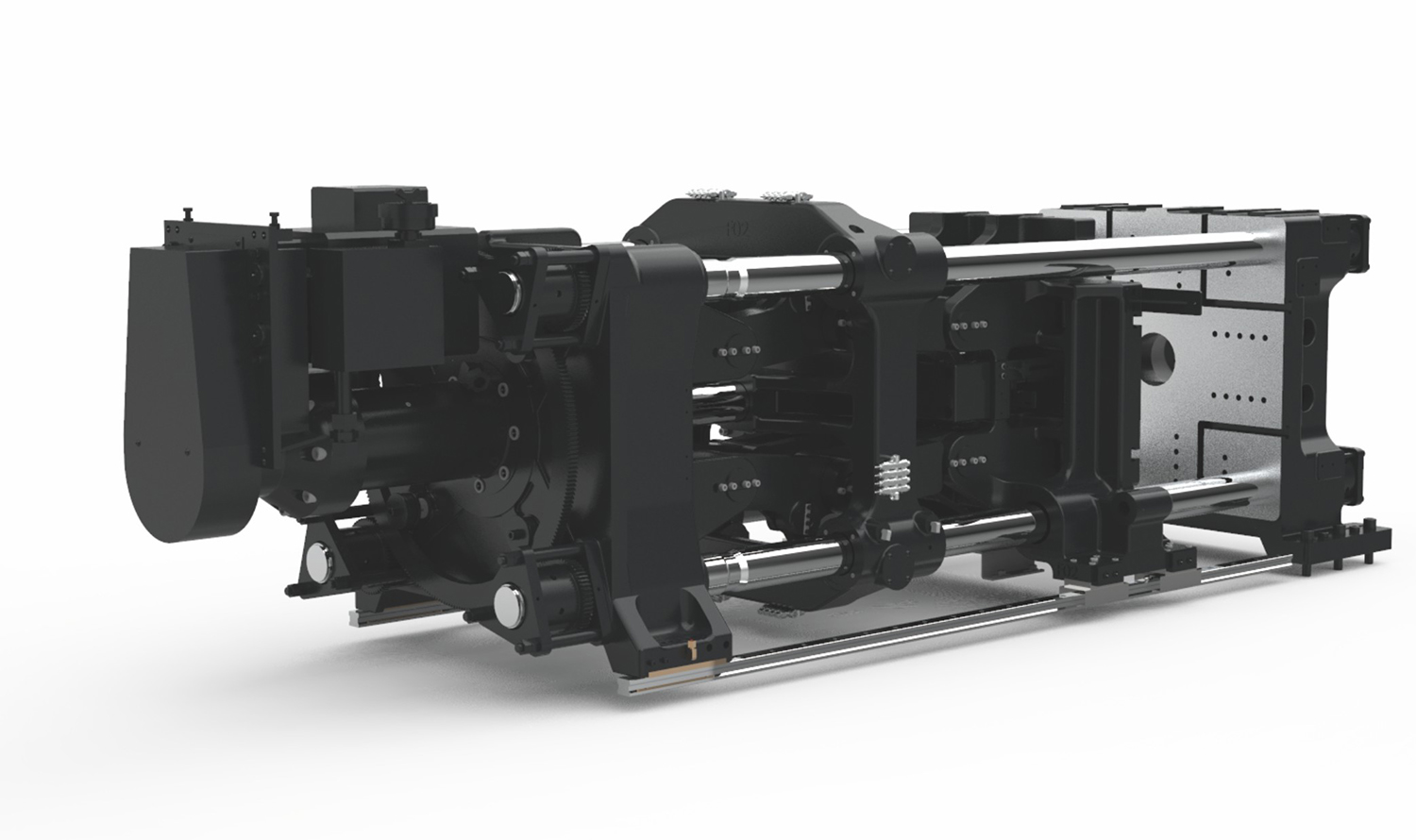

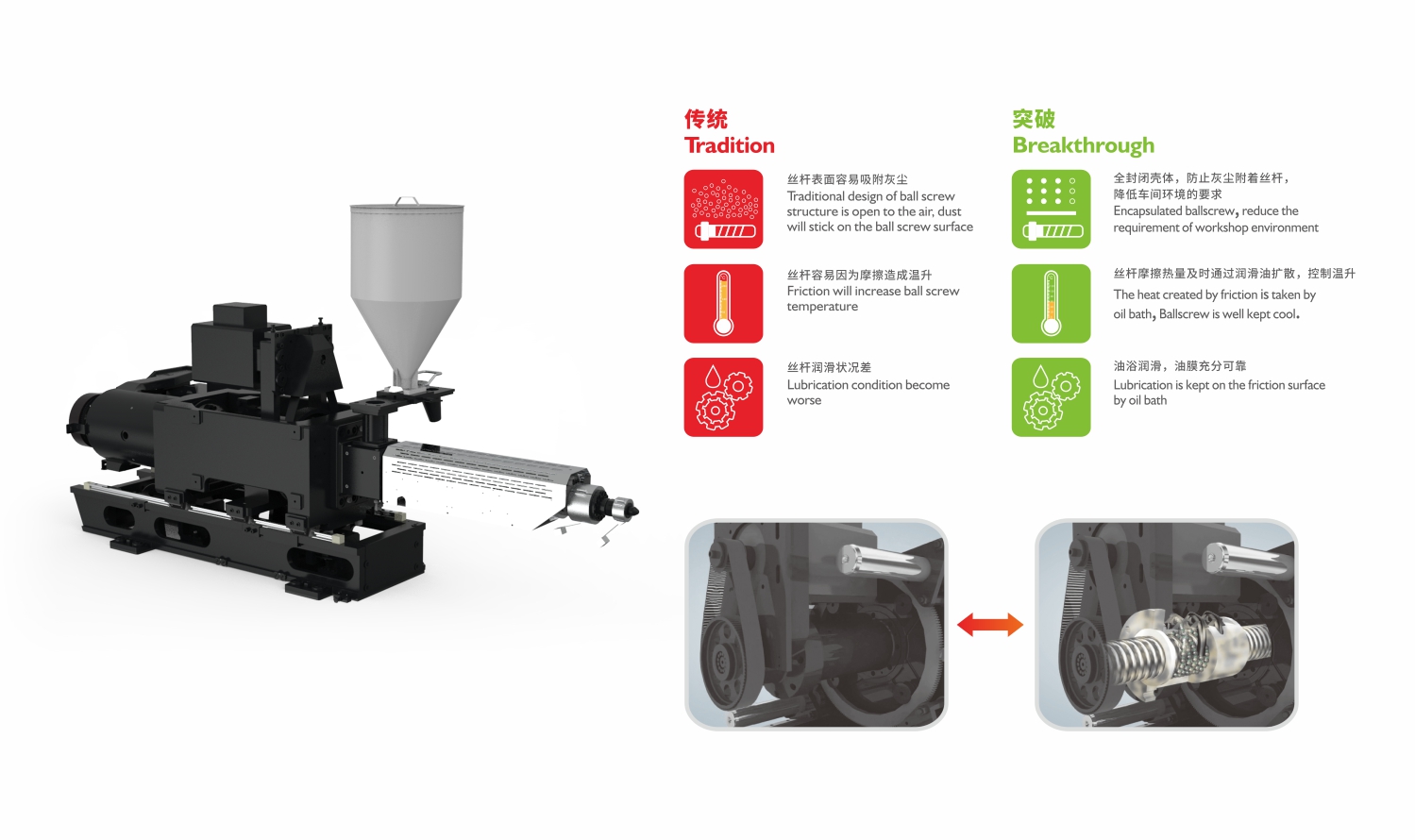

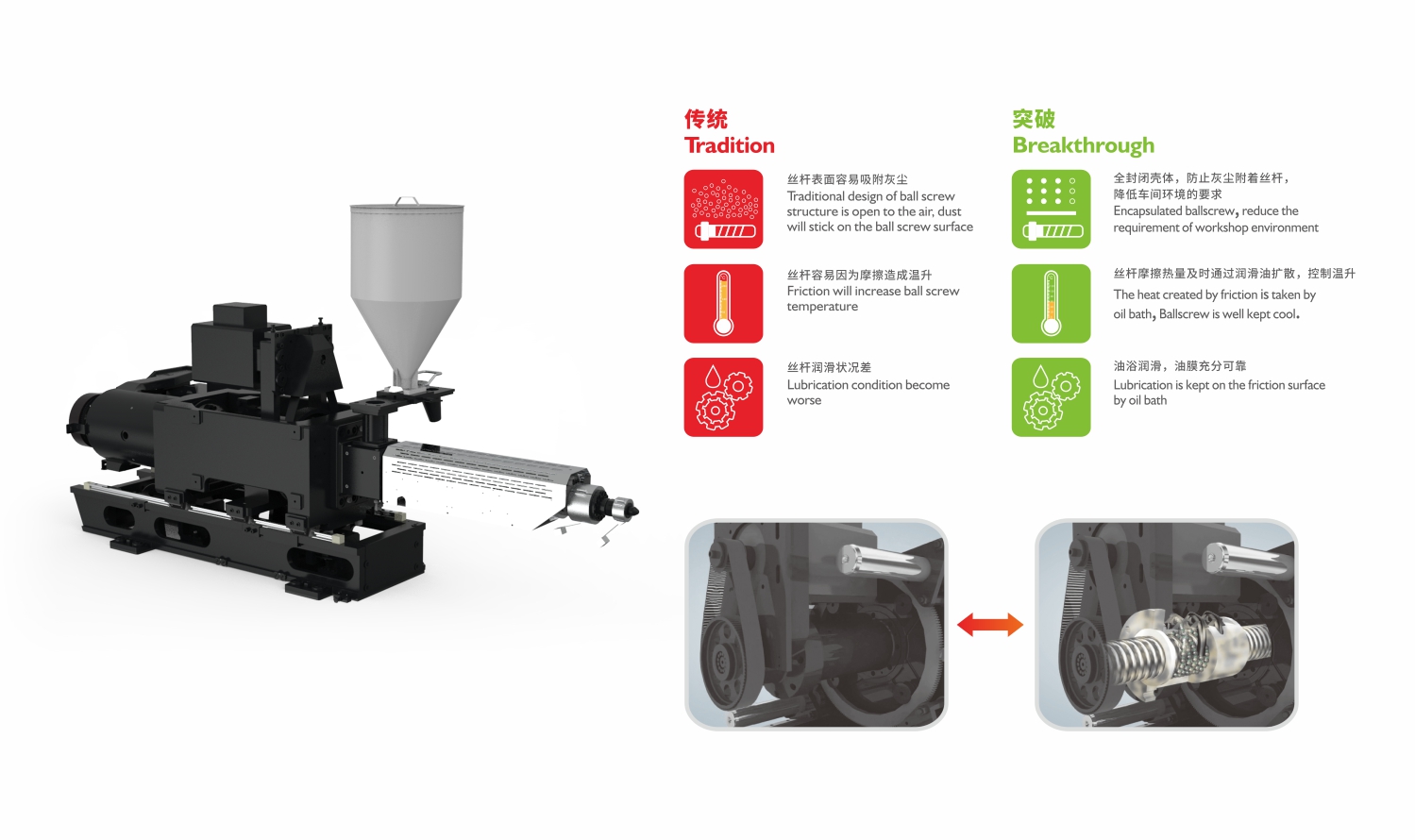

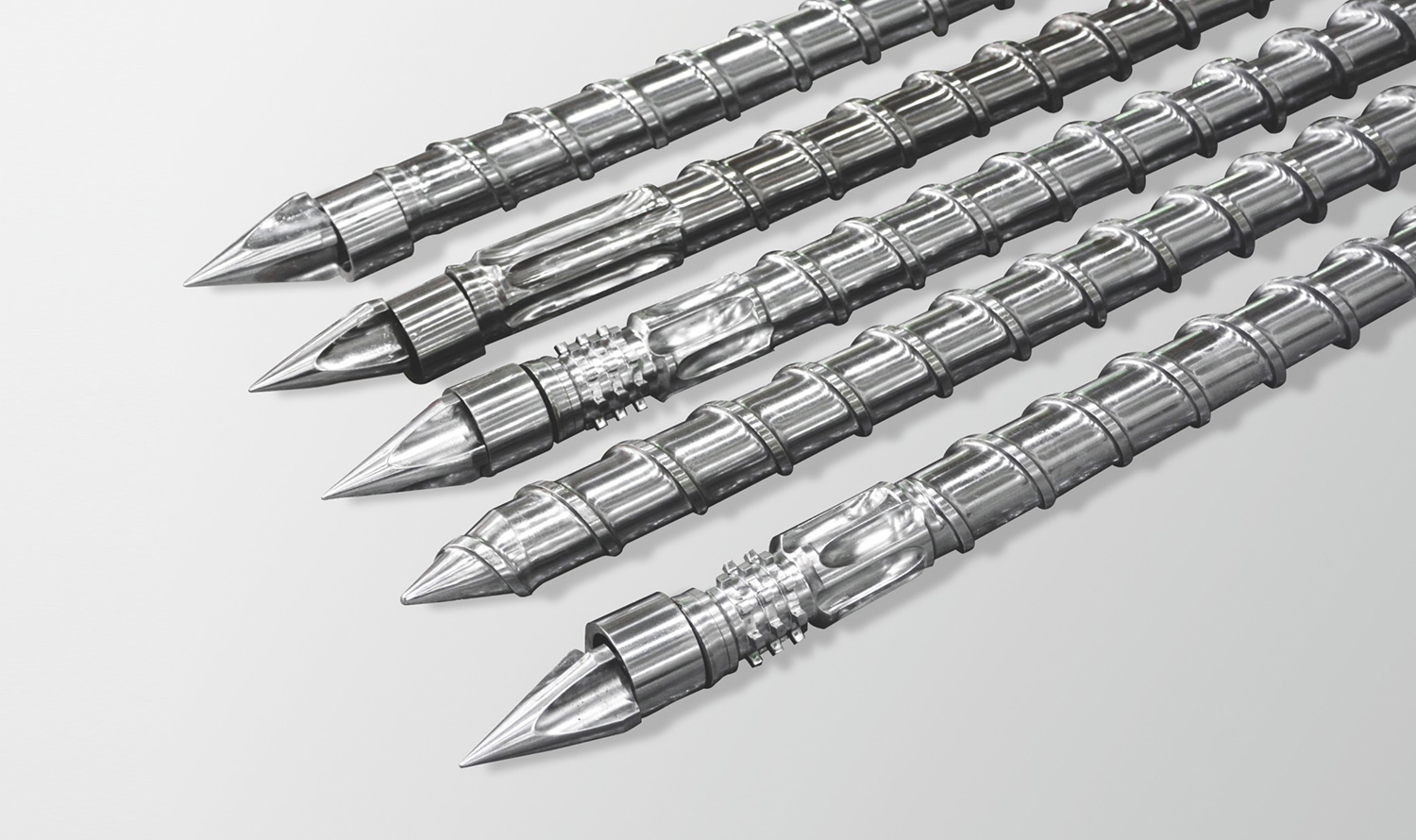

·The fully enclosed shell prevents dust from adhering to the screw, reducing the requirements for the workshop environment;

·The friction heat of the screw is diffused through the lubricating oil in time to control the temperature rise; oil bath lubrication, the oil film is sufficient and reliable;

·The friction heat is quickly taken away, reducing the temperature of the screw, reducing Wear; no need to use expensive imported screw grease:

·Block dust pollution, low requirements on the use environment; simple maintenance, no need to clean sludge;

·Patented closed injection structure design, dustproof, immersion, lubrication, improve screw life.

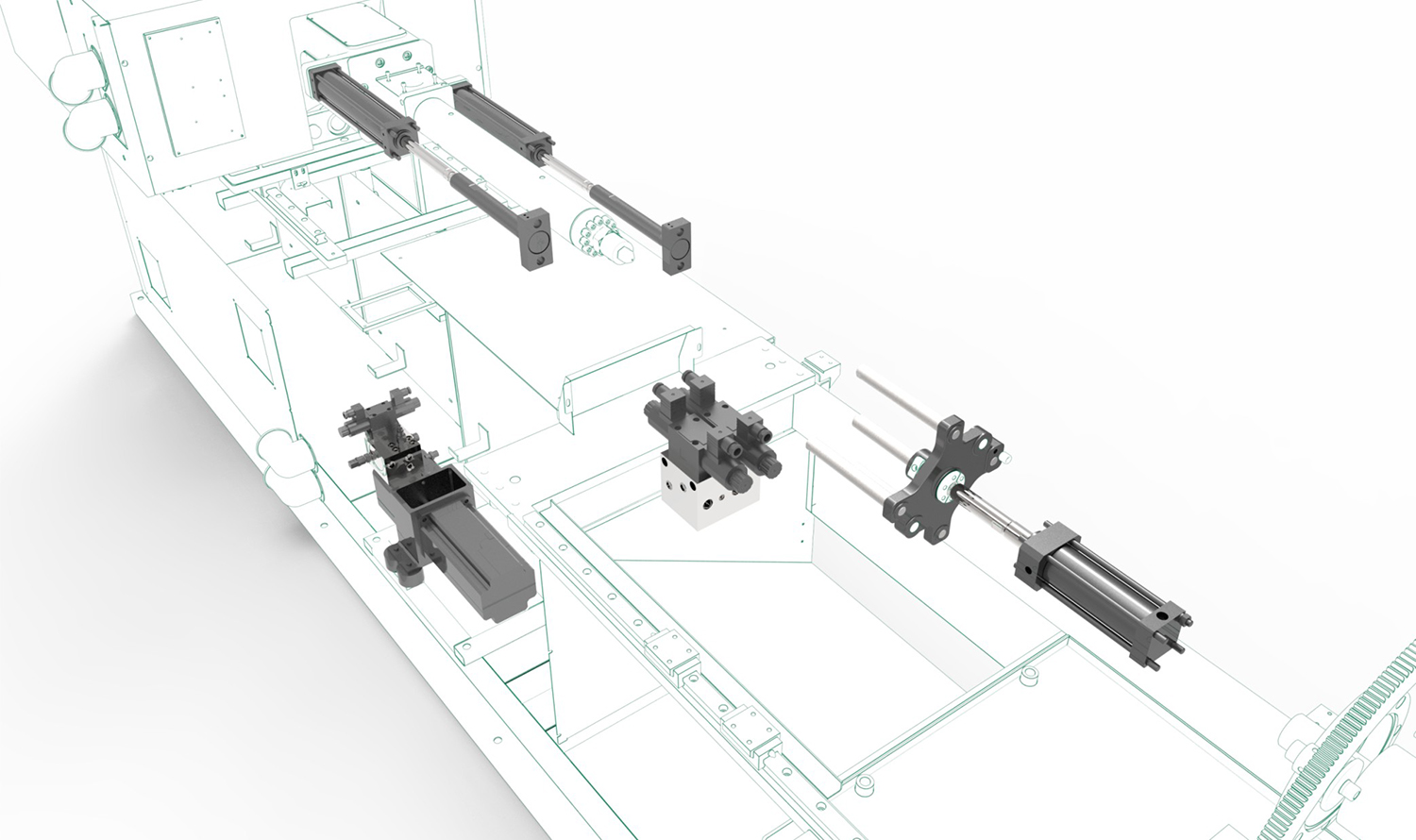

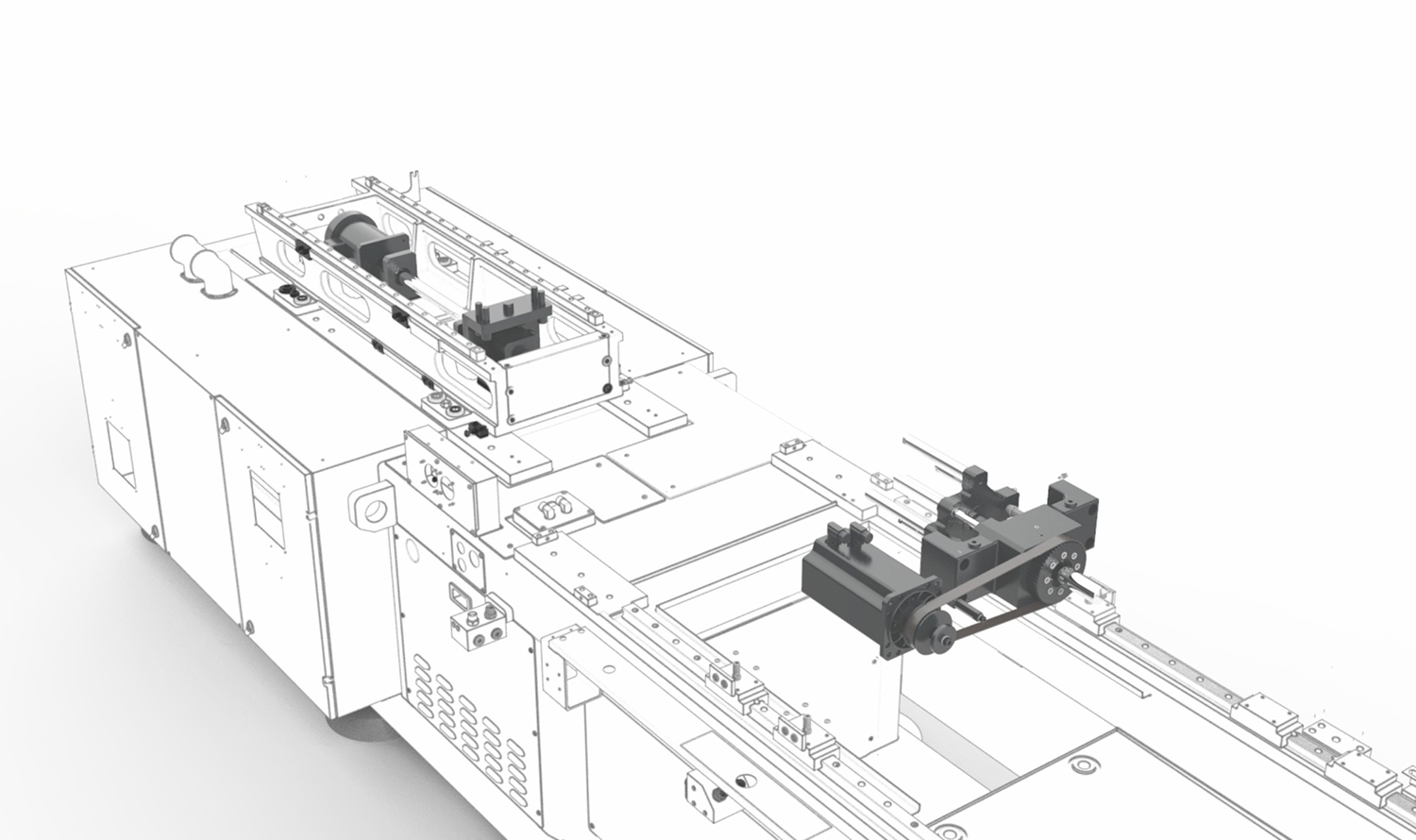

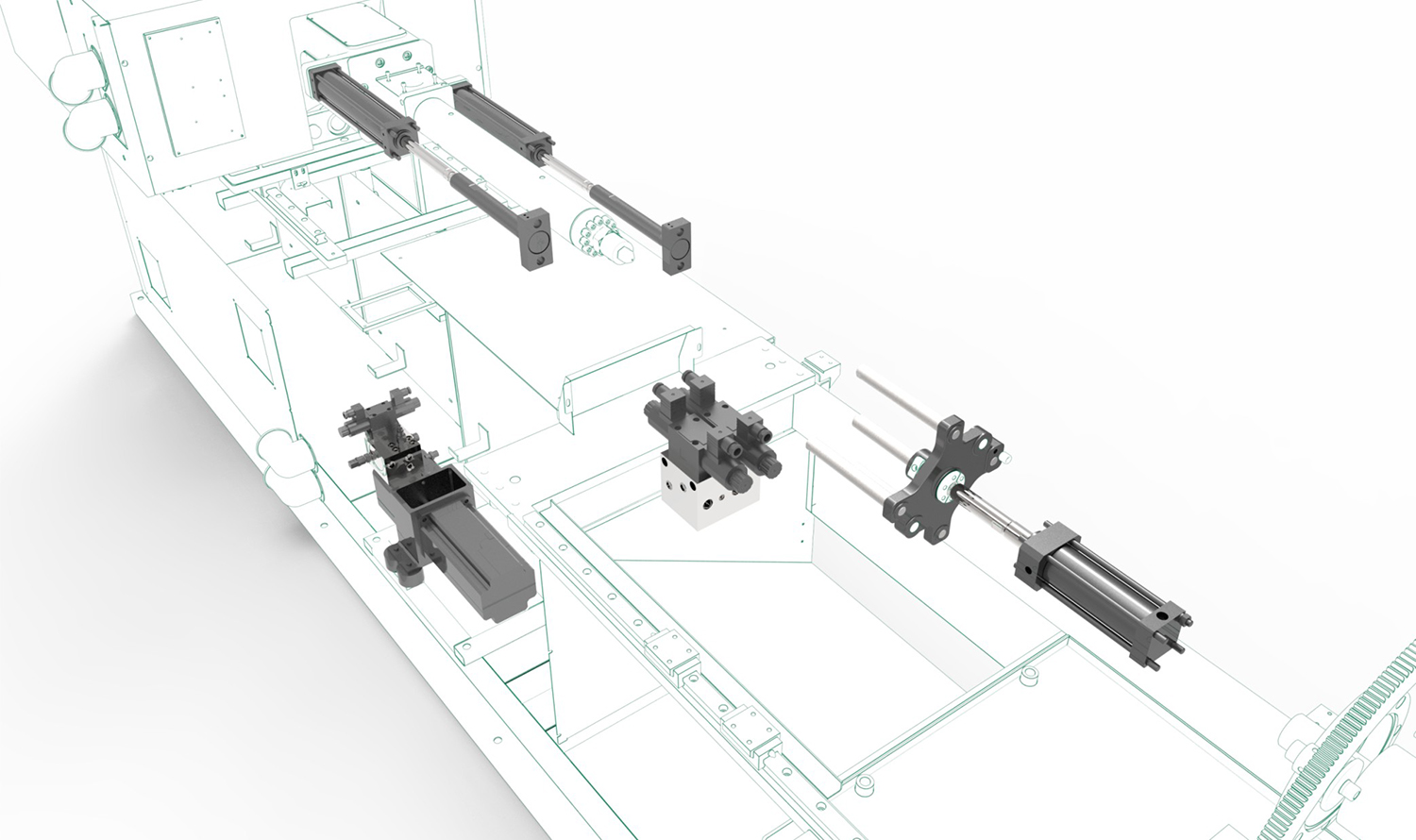

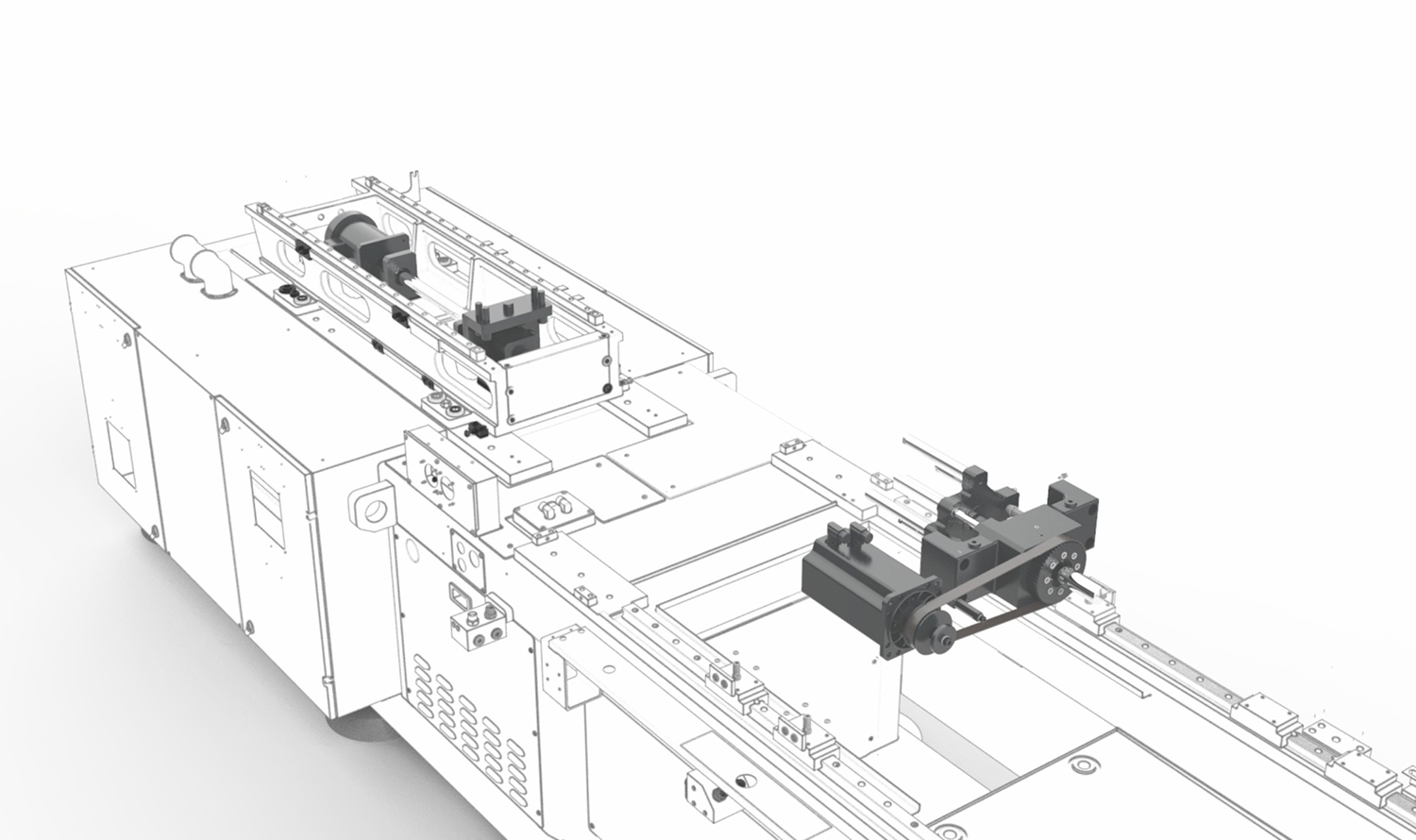

·Symmetrical shift shot, the force on the nozzle top is more balanced and reliable;

·Servo driven pump station, more energy-saving and efficient;

·Standard hydraulic ejection and neutron functions, flexible to meet the use of different molds.

·Symmetrical shift shot, the force on the nozzle top is more balanced and reliable:

·Servo-driven pump station, more energy-saving and efficient;

·Standard equipped with hydraulic ejection and neutron functions, which can flexibly meet the use of different molds.

·All-electric configuration, with standard neutron signal emitter and ejection motor drive

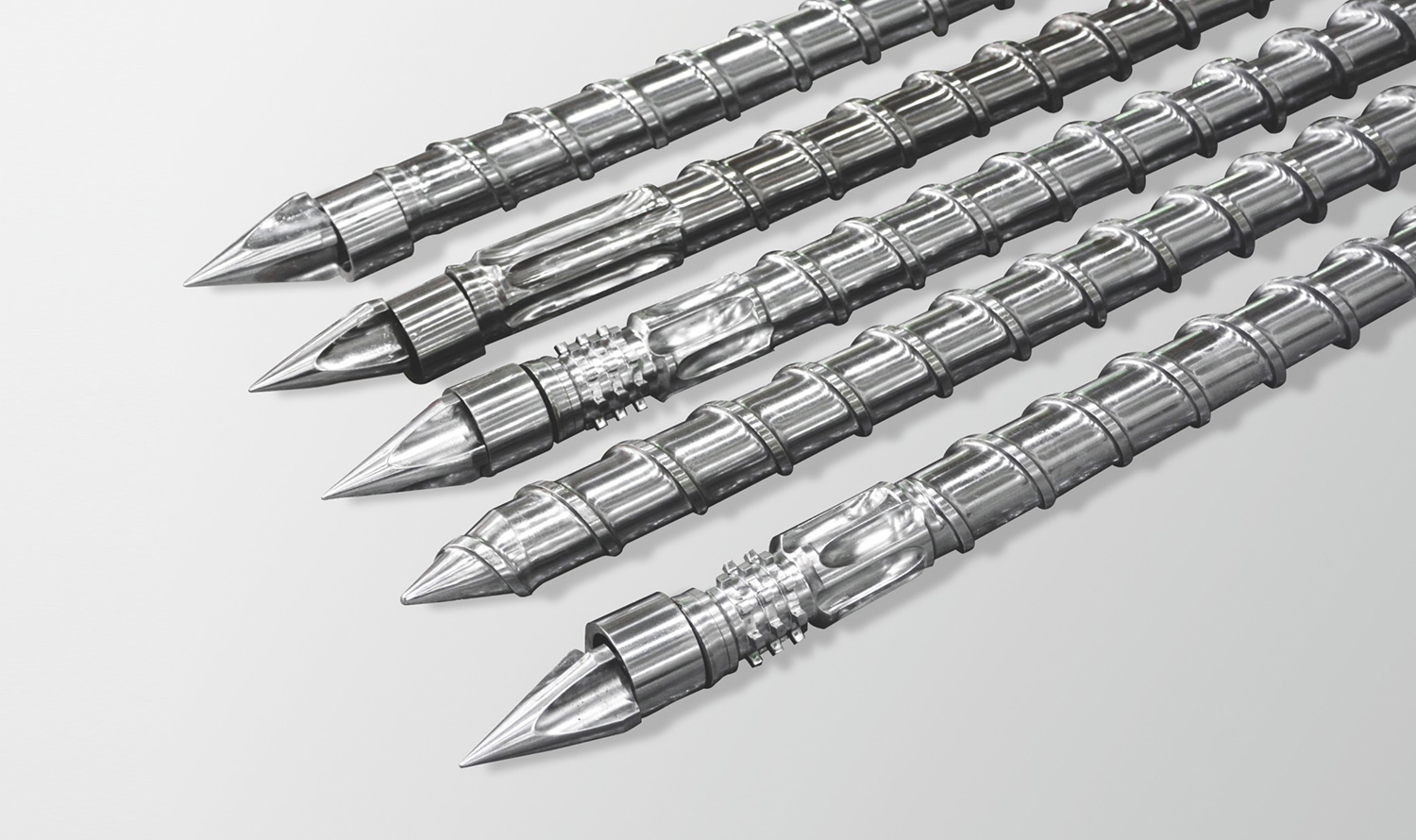

·Excellent plasticizing effect;

·Screw solutions to meet various applications.