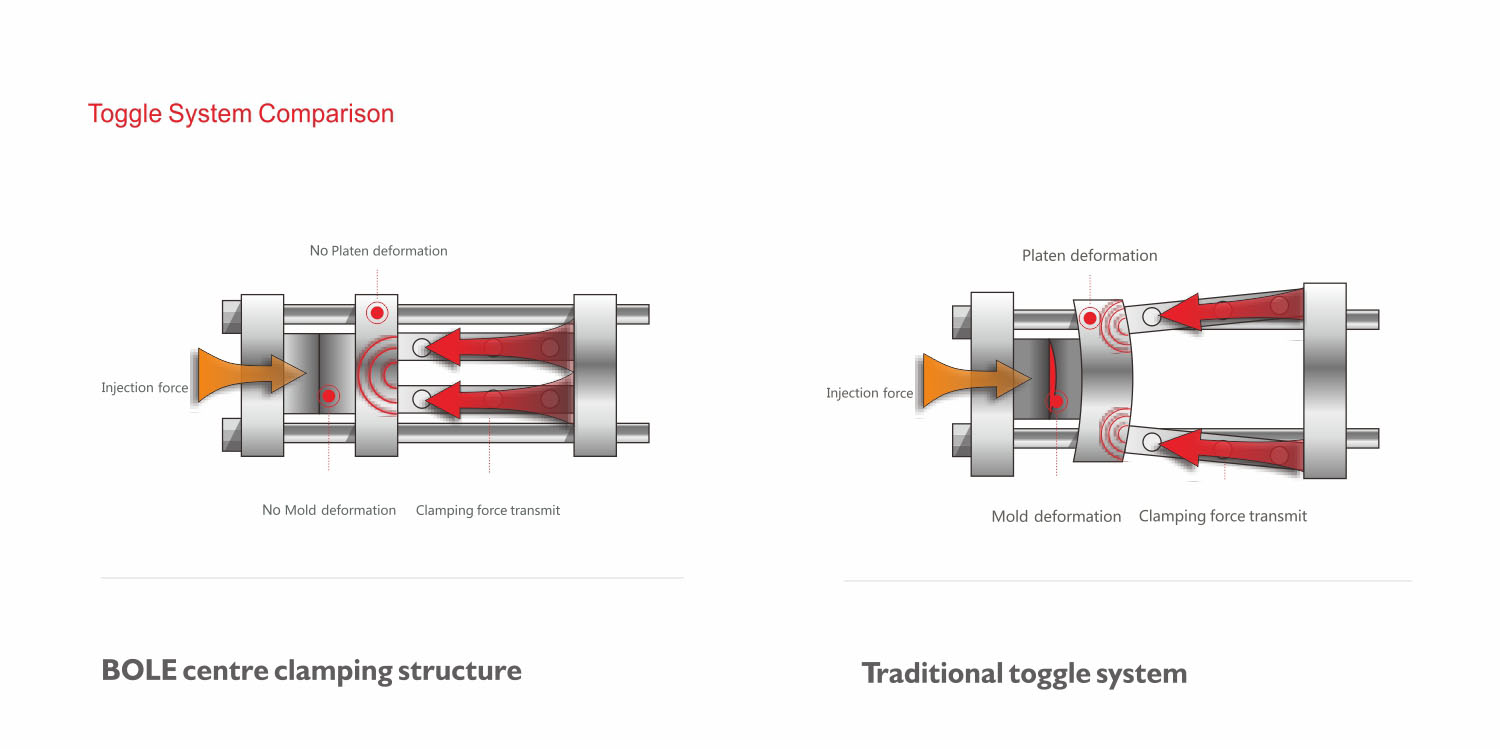

EKS-SP center clamping

High-speed packaging machine

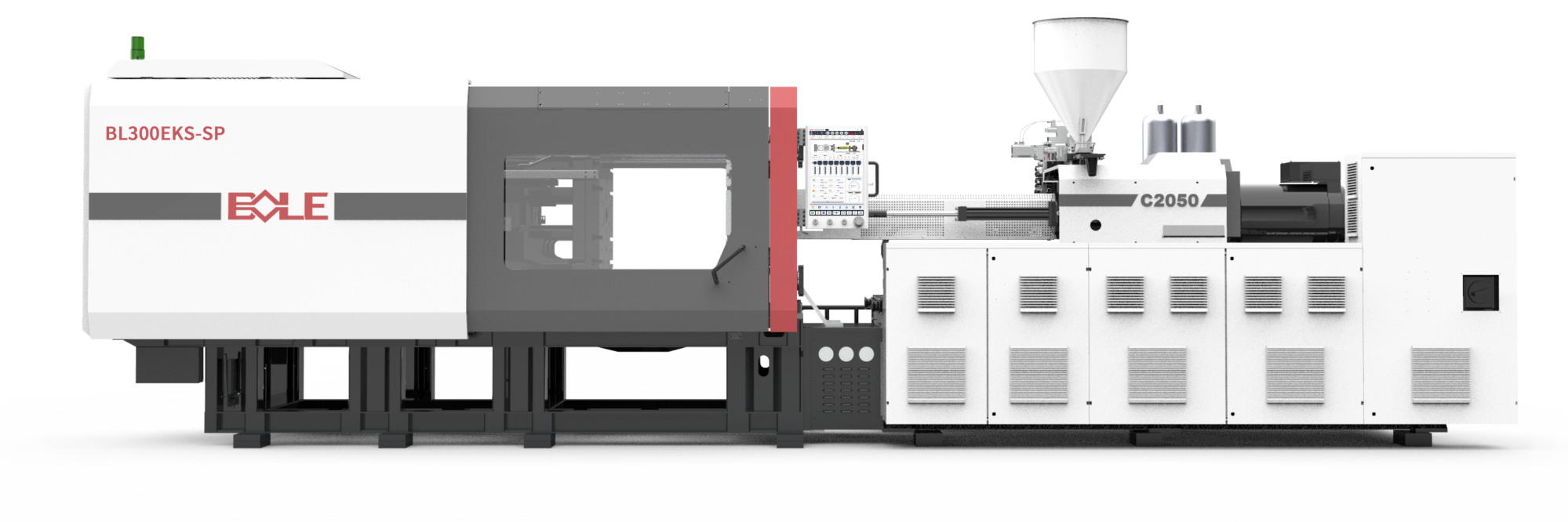

EKS-SP

Central clamping high-speed packaging machine

EKS-PB

Central clamping barrel type high-speed packaging machine

HK

Special machine for thin-walled high-speed packaging

BL-EKS

Fast special machine series

EKW-DW

Center clamping machine for fast packaging of daily necessities

EKS-SP

Central clamping high-speed packaging machine

EKS-PB

Central clamping barrel type high-speed packaging machine

HK

Special machine for thin-walled high-speed packaging

BL-EKS

Fast special machine series

EKW-DW

Center clamping machine for fast packaging of daily necessities

National invention patent center clamping

Control system

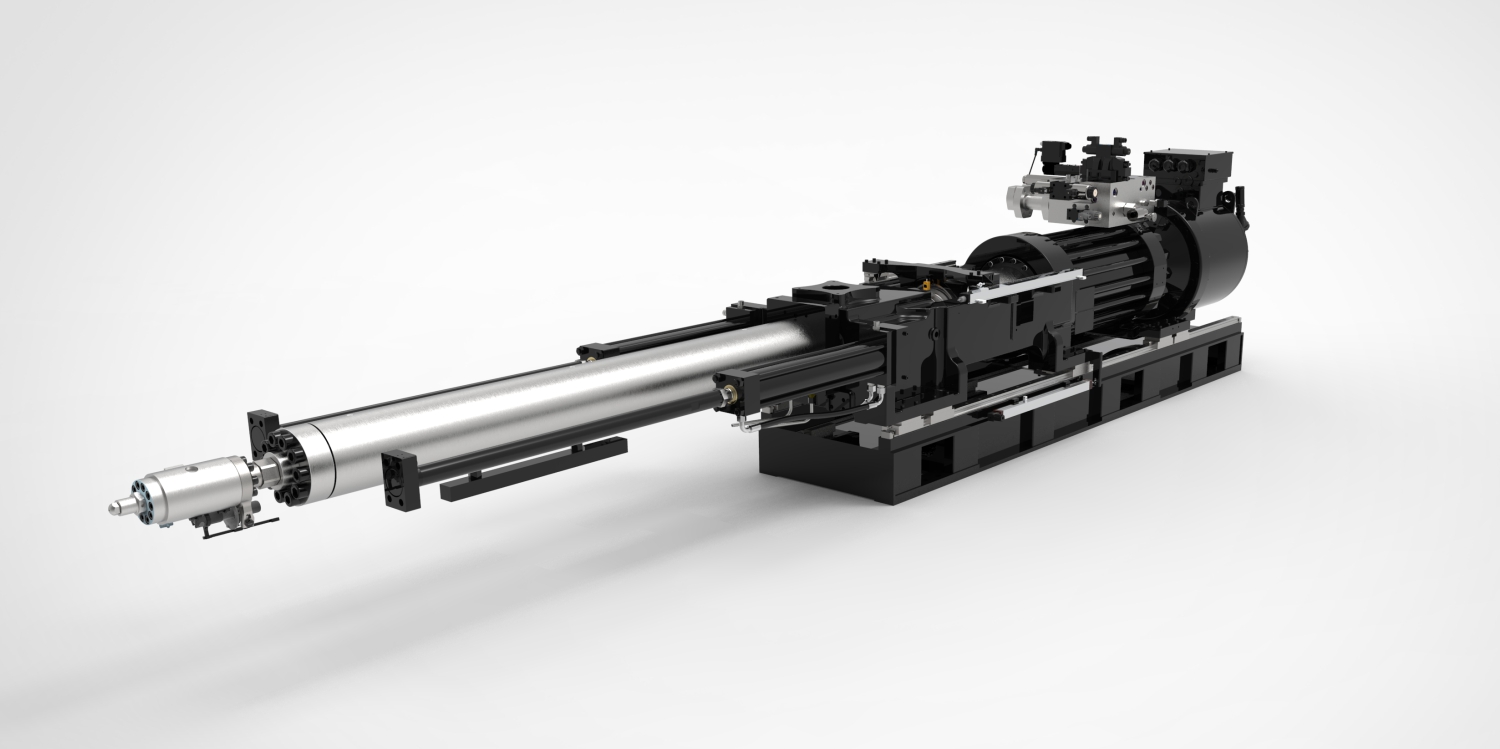

Injection unit

Plasticizing system designed in Germany