Exhibition Preview | Bole Intelligent sincerely invites you to attend the 2025 Shanghai Die Casting Exhibition

2025 上海压铸展

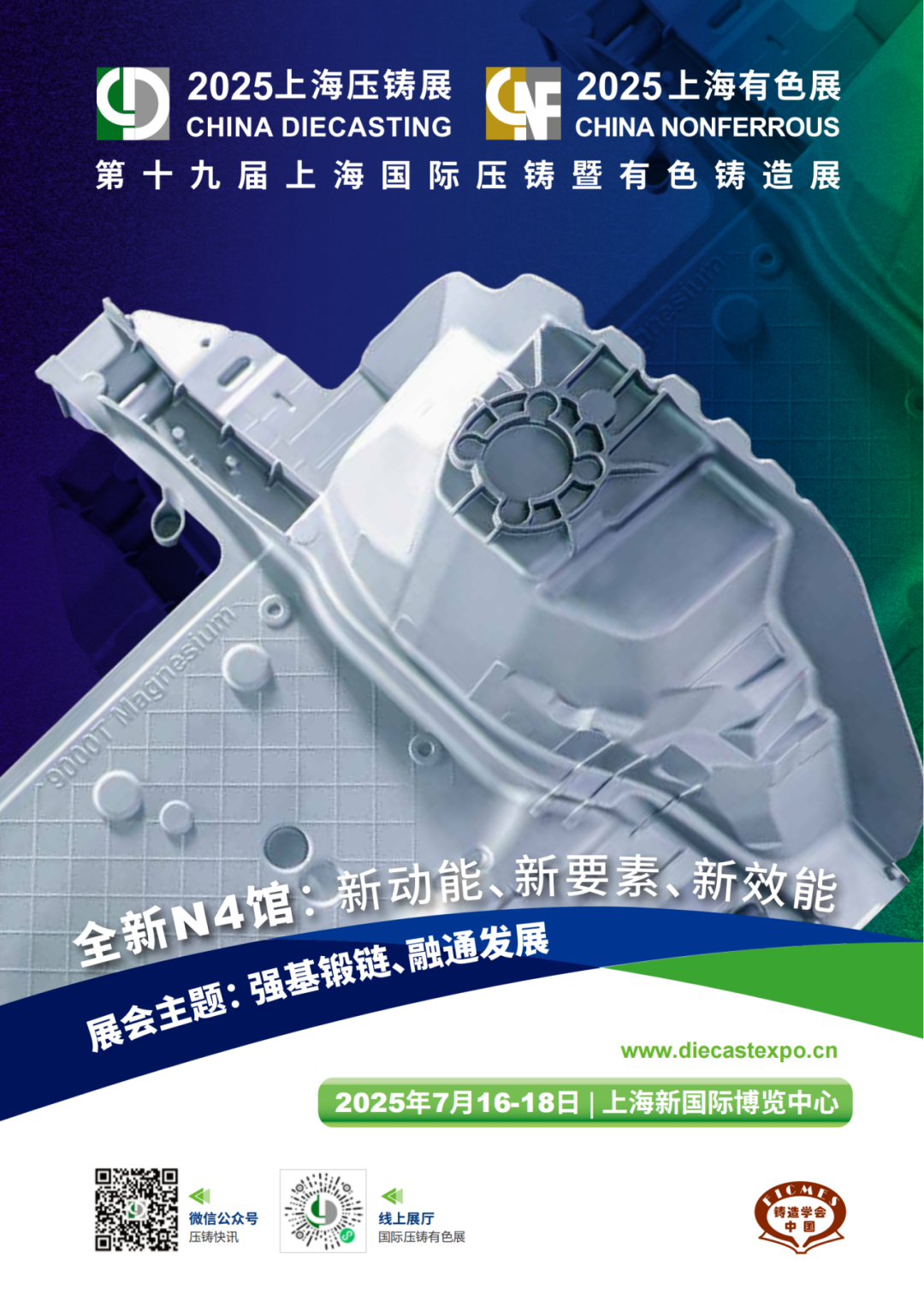

The 19th Shanghai International Diecasting & Nonferrous Foundry Exhibition will be held in Halls N1-N4 of the Shanghai New International Expo Center from July 16-18, 2025. Leveraging the resources of over 30 member countries of the World Foundry Organization, the exhibition brings together leading companies and professionals from the global foundry and diecasting industry to explore cutting-edge technologies, innovative concepts, and market trends, ultimately driving the global development of the industry.

In recent years, the global manufacturing industry has been shifting toward green, efficient, and lightweight manufacturing. Magnesium alloys, due to their low density (two-thirds that of aluminum and one-quarter that of steel) and high specific strength, are widely used in the automotive and consumer electronics sectors. They hold great potential in lightweighting and improving the range of new energy vehicles. As the world's largest magnesium resource holder, China is accelerating the industrialization of magnesium alloys.

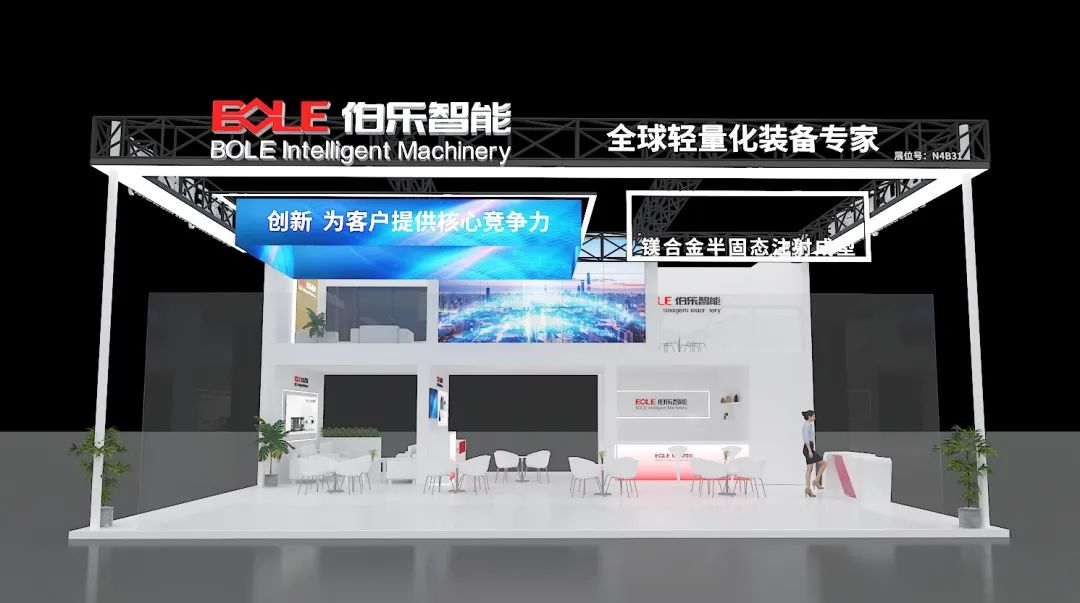

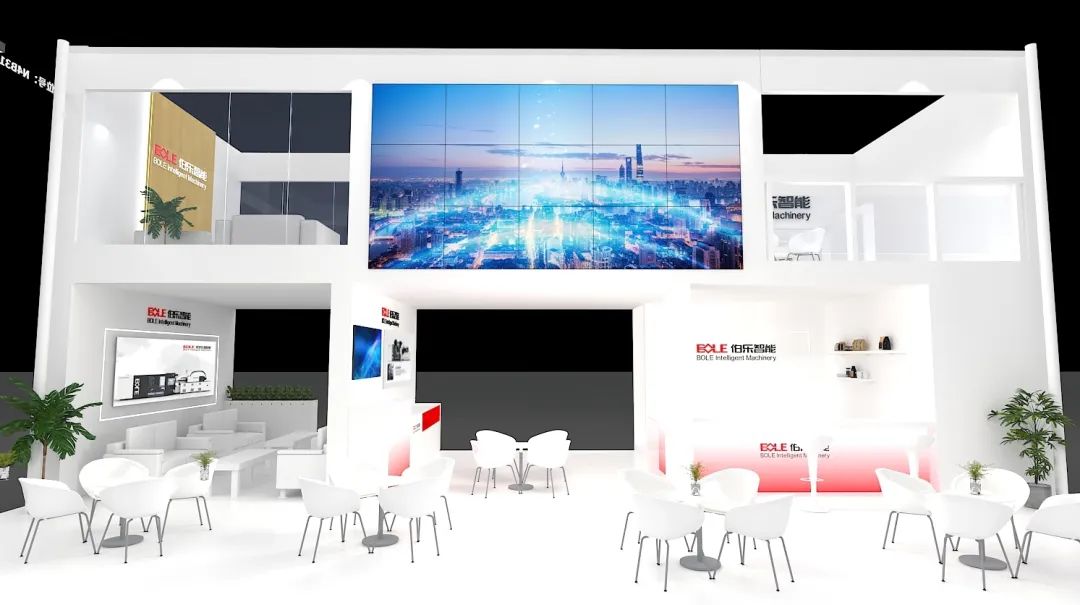

As a leading domestic company in high-end injection molding and magnesium alloy forming equipment, Bole Intelligent will showcase a two-platen magnesium alloy semi-solid injection molding machine in Hall N4 of the exhibition, providing the industry with efficient and environmentally friendly lightweight solutions.

1. Super large clamping force and high precision control:

The model on display this time adopts a two-platen structure and an optimized clamping system to ensure high-precision forming of large magnesium alloy parts (such as automobile shock towers, motor housings, wheel hubs, etc.).

2. Green and efficient process: No protective gas is required, avoiding the SF6 pollution problem of traditional die casting; near-net-shape molding reduces subsequent processing and increases material utilization by more than 30%; energy consumption is reduced by 50%, making it more economical than traditional die casting36.

3. Wide range of industry applications: Suitable for new energy vehicle structural parts, 3C electronic ultra-thin parts, 5G communication housings, etc., supporting the "magnesium replacing aluminum" strategy.

Exhibition time

July 16-18

Booth Information

N4B31

With the surge in demand for magnesium alloys in the lightweight market, semi-solid injection molding technology is becoming a new trend in the industry. At this exhibition, Bole Intelligent, leveraging its independently developed large-scale, intelligent equipment, will provide global customers with superior solutions, pushing magnesium alloy manufacturing to a higher level.

Welcome to visit the Bole Intelligent booth in Hall N4 (Booth No.: N4B31) to discuss the future of magnesium alloy forming technology!