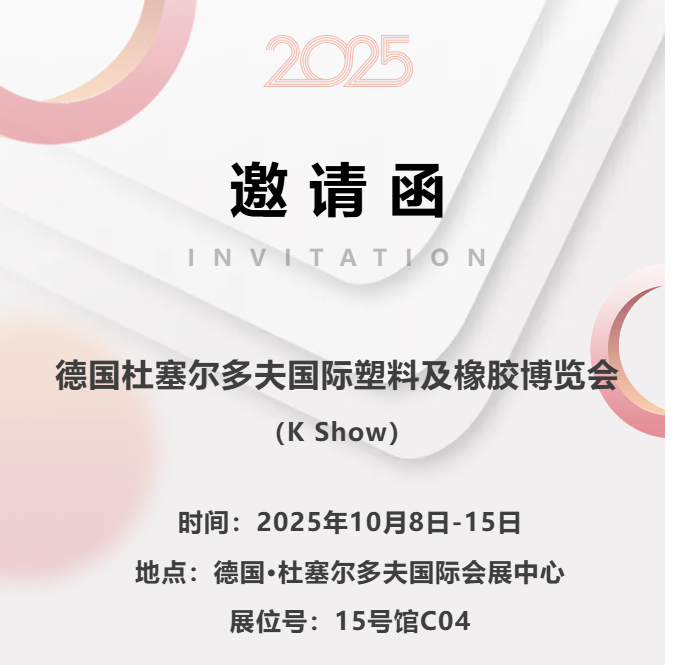

The International Plastics & Rubber Fair (K Show) in Düsseldorf, Germany, is the world's premier event for the plastics and rubber industry. Held every three years, it brings together innovative technologies and professionals from around the world. Themed "The Power of Plastics: Greening the Future, Creating Extraordinary Intelligence, and Sharing Responsibility," the 2025 edition will focus on circular economy, digitalization, and sustainable solutions. The show is committed to addressing global industry challenges, consolidating its global leadership, and promoting in-depth communication and cooperation across the industry chain. Bole Intelligent Equipment Co., Ltd. will showcase a variety of innovative technologies and intelligent solutions (Booth No.: Hall 15, C04), showcasing the power and innovative spirit of Chinese intelligent manufacturing to the world!

2025-09-19

Recently, Bole Intelligent Equipment Co., Ltd. held a warm and grand birthday celebration for its Indian agent, Mr. Pandey. The gathering, themed "Intelligent Connectivity for the Future, Warmth Between India and China," brought together representatives from the client company KSP, the Indian agent team, and members of Bole Intelligent's International Marketing Center. Through technological achievements demonstrations, cultural interactions, and strategic announcements, the event vividly illustrated the practical implications of "globalization and localization."

2025-09-19

Recently, Bole Intelligent Equipment Co., Ltd. held a heartwarming and grand birthday celebration for its Indian agent, Mr. Pandey. Themed "Intelligently Connecting the Future, Warming India and China," the gathering brought together representatives from client company KSP, the Indian agent team, and members of Bole Intelligent's International Marketing Center. Through technological achievements, cultural interactions, and strategic announcements, the event vividly demonstrated the practical implications of "globalization with localization."

2025-09-19

Recently, to establish role models and enhance the effectiveness of practical education, the Youth League Committee of Shanghai Jiao Tong University organized a summer social practice program for 2025. A lightweighting practice exchange team from Shanghai Jiao Tong University, composed of faculty and students, visited Böhler Intelligent Equipment Co., Ltd., a global leader in intelligent equipment, for an in-depth exchange activity themed "Breakthroughs and Industrial Applications of Magnesium Alloy Lightweighting Technology." Both sides discussed cutting-edge topics such as the trend of lightweighting in new energy vehicles and magnesium alloy semi-solid injection molding technology. They also visited Böhler's ultra-large magnesium alloy semi-solid injection molding machine and 20-inch magnesium alloy wheel production line, witnessing the fruitful results of industry-academia-research collaborative innovation.

2025-09-19

To establish a model and enhance the effectiveness of practical education, the Shanghai Jiao Tong University Youth League Committee recently organized its 2025 Summer Social Practice Program. A team of teachers and students from Shanghai Jiao Tong University, known for their lightweighting practices, visited Bole Intelligent Equipment Co., Ltd., a global leader in intelligent equipment, for an in-depth exchange focused on the theme of "Magnesium Alloy Lightweight Technology Breakthroughs and Industrial Applications." The two sides discussed cutting-edge topics such as lightweighting trends in new energy vehicles and magnesium alloy semi-solid injection molding technology. The two sides also visited Bole's ultra-large magnesium alloy semi-solid injection molding machine and 20-inch magnesium alloy wheel production line, witnessing the fruitful results of collaborative innovation between industry, academia, and research.

2025-09-19

On September 5, 2025, the 7th China (Chongqing) International Plastics Industry Exhibition grandly opened at the Chongqing International Expo Center. Themed "New Quality Leading, Innovation Empowering," this year's exhibition brought together over 300 leading companies from the global industry chain, covering nine core areas including plastics processing machinery, intelligent automation equipment, and green environmental protection technologies. Bole Intelligent Equipment Co., Ltd. made a stunning appearance with its star product, the EVOlution hybrid intelligent injection molding machine, and engaged in in-depth discussions with leading manufacturing companies in central and western China to jointly explore new paths for high-quality development of the plastics industry.

2025-09-19